Our focus throughout 2025 remained consistent: supporting pipeline owners and operators with equipment, training, and technical support that works in real-world conditions.

These 10 real-world applications show how closed-vent compression systems support emissions reduction while keeping daily pipeline maintenance efficient and safe.

What combines the strength of steel, the efficiency of modern plastics, and the safety standards the industry demands? DuraPlas TuffStand pipe stands.

Industry tests show promise for non-welded repair of oil and gas pipeline circumferential cracks.

A recent joint industry project led by C-FER Technologies has shown promising results for using Petrosleeve, a non-intrusive repair method, to arrest circumferential crack growth in pipelines.

The multi-phase JIP is testing a range of non-welded repair technologies to determine if they are a safe and cost-effective alternative to repair circumferential cracks compared with traditional methods.

At the 2025 Pipeline Pigging and Integrity Management (PPIM) Conference, PeroSleeve’s Bob Smyth reported on Petrosleeve’s results within the JIP, producing a paper titled Interim Results from the JIP Evaluation of Repair Technologies for Circumferential Cracks on Pipelines of the Steel Compression Reinforcement Sleeve; Repair F (PetroSleeve). This article is a summary of his presentation.

Why research for circumferential crack non-welding repair matters

Traditional repair methods for circumferential cracks typically involve removing the damaged section of pipe or installing a welded Type B sleeve. But both come with tradeoffs. Cutting out pipe can be expensive and disrupt operations, while in-service welding adds complexity and additional risks.

Non-welding solutions offer a fast installation option with less equipment required than metal sleeves, plus the flexibility to repair pipe with non-uniform geometries or where in-service welding may not be feasible.

To explore non-intrusive options, the JIP brought together stakeholders to test six non-intrusive repair technologies. One of them — referred to as “Repair F” in the study — was Petrosleeve.

What is Petrosleeve?

Petrosleeve offers a simple, non-intrusive alternative to traditional forms of circumferential crack repair.

It’s a two-part steel sleeve that clamps around the pipe and is joined by external sidebars – with no welding to the host pipe required. During installation, the pipeline is slightly pressurised, putting the pipe into compression and the sleeve into tension. This creates a tight mechanical bond that helps prevent crack propagation.

Before installation, key parameters like wall thickness, internal pressure, flow rate, and pipe temperature are used with proprietary software to tailor the installation of the repair for each site.

How the circumferential crack non-welding repair methods were tested

C-FER’s JIP evaluated six non-intrusive repair options through a rigorous four-phase program, involving performance tests under pressurised conditions on X52-grade pipe.

The non-intrusive methods tested included wet lay-up, composite fabric, preformed composite coil, steel sleeve, or bolt-on repair sleeve/collar.

Repair F (Petrosleeve) demonstrated robust structural performance across all phases.

Phase 1: structural strength

The repair systems were installed on three sections of 24-inch X52 pipe pressurised to 785 psi (5,400 kPa) to mimic real pipeline conditions.

Each system was subjected to various non-destructive tensile testing situations to compare axial stiffness. This included pressure cycling before being pressurised to 1,170 psi (8,060 kPa) with axial tension applied until a section of the control pipe reached plastic collapse.

Following Phase 1, only three repair methods were selected to participate in further testing. Repair F was deemed acceptable for further testing.

Petrosleeve installed on the pipe specimens used during Phase 1 of the JIP.

Phase 2: installation pressure effects

Phase 2 explored how internal pressure during installation affects repair performance via tests on seven 12-inch vessels pressurised at 30 per cent, 50 per cent and 70 per cent of specified minimum yield strength (SMYS). The vessels were put under tension, and at 72 per cent SMYS, put under tension until failure.

Results showed consistent behavior of Repair F across various pressures, maintaining favorable stiffness ratios, load sharing and strain compatibility with the host pipe. Following Phase 2, Repair F was one of two repair methods deemed acceptable for further testing.

Phase 3: real crack testing

This critical phase introduced simulated circumferential cracks — up to 80 per cent through-wall depth — to evaluate how the repair systems performed under extreme conditions. Each repair system completed the destructive tensile test under varying pressures until they failed.

Photo illustrating the 80 per cent simulated crack.

Each vessel was pressurised to 62.5 per cent SMYS to confirm the crack wouldn’t rupture during the installation of each repair method. The systems were then installed at 50 per cent SMYS and exposed to pressure variances. At 72 per cent SMYS (1,482 psi/10,200 kPa), the vessels were put under tension until failure occurred by increasing tension until the host pipe entered the plastic range and the crack opened.

During Phase 3 tensioning.

Repair F effectively contained the defect under normal operational pressures. The pipe only failed when reaching the plastic range under high tension at 560 Kip (560,000 lb-force) — a level of strain unlikely outside of severe events like landslides or earthquakes. This indicated good containment up to extreme loading.

Phase 4: long-term durability (ongoing)

Phase 4 assesses long-term performance under cyclic pressure. In this test, the participating repair systems were installed on three vessels with an 80 per cent simulated circumferential crack before being put under tension and load to simulate field conditions.

The Repair F Petrosleeve specimens tested in this phase completed 1,000 hours without leaking.

What the interim results show

So far, key observations from the study include evidence of compressive pre-stress between Petrosleeve and the pipe, with crack containment maintained until significant yielding occurs in the parent metal.

Petrosleeve’s results in Phase 3 showed that the repair method only failed when the steel was in the plastic range, with the steel at the edge of the sleeve yielding, reducing the circumference of the pipe and breaking the compressive bond between the pipe and sleeve. This exposed the crack to the tensile force, stretched the steel, and the crack opened.

This suggests Repair F could reliably contain circumferential flaws under normal operational stresses, with failure only likely in rare, high-strain events, such as major geohazards like landslides or earthquakes.

A potential reliable alternative to traditional methods for repairing pipeline circumferential cracks

While testing is ongoing, the early results are promising. Repair F (Petrosleeve) has demonstrated credible performance across short-term mechanical and pressure testing. Ongoing long-term testing will further validate its field viability as a non-welded option for circumferential crack repair.

Petrosleeve could offer pipeline operators a non-intrusive, safe, effective repair method for circumferential cracks — without shutting down operations or risking the hazards of hot welding.

The early JIP results indicate that it can contain significant crack defects and maintain integrity until extremely high strain levels are reached — beyond what most operational scenarios would impose.

For more information on Petrosleeve, contact its exclusive agent for Oceania: Tremco Pipeline Equipment a sales@tremcopipelineequipment.com.au

Sawyer Manufacturing Company’s pipeline rim clamps provide an easy solution for tough pipe reforming jobs. Watch Sawyer’s step-by-step instructions on how to use the clamp for maximum accuracy and minimal downtime.

Suitable for pipe sizes from 4 inches to 72 inches, Sawyer’s manual lineup Rim Clamp is designed for use on out-of-round pipes that require a high level of alignment accuracy. The Rim Clamp can reform 45,000 PSI tensile strength pipe up to Schedule 80, with out-of-round conditions of up to 2 inches (51 mm) depending on wall thickness. For larger jobs, Sawyer’s heftier Ultra Rim Clamp can provide the same benefits.

The Rim Clamp being used in the field. Image courtesy of Sawyer Manufacturing Company.

Why choose the Sawyer Rim Clamp?

Sawyer Manufacturing Company has been designing and manufacturing pipeline and welding equipment in the USA since 1948, and has a long-standing 20+ year partnership with Tremco Pipeline Equipment to supply its equipment to the Oceania region.

Sawyer’s rim clamps:

- High reforming capacity: handles up to X45 Schedule 80 pipe with tensile strength up to 45,000 PSI and up to 2″ out‑of‑round conditions, depending on wall thickness

- Rigid shell design: offers a robust external alignment solution, preferred by users who need consistent accuracy and reliability over flexible chain clamps

- Efficient setup: The jackscrew setting gauge speeds setup and ensures repeatable precision.

- Safe and stable: heavy‑duty galvanised construction, pivoting pads on jackscrews, and a secure latch mechanism provide stability and safety in field conditions

- Thoughtful tools: each rim clamp also comes with a set of tools for operation, including a torque wrench, speed handle, and socket for reliable pressure control and efficient operation.

The Rim Clamp. Image courtesy of Sawyer Manufacturing Company.

How do pipeline rim clamps work?

The rim clamps feature multiple heavy duty, galvanised jackscrews, which give the user the ability to apply precise reforming pressure on specific areas of pipe. The specialised torque wrench supplied with the clamp furthers this capability by allowing the user to set the exact torque required for the reforming application, saving time and effort by setting the perimeter of the jackscrews before the external line up clamp is placed on the pipe. The unique jackscrews on Ultra RIM Clamps have trapezoidal thread, which makes them stronger than conventional jackscrews and able to assert more reforming pressure on the pipe.

Hinged flip-up jackbars allow for simple pipe mating, and also ensure the clamp can be used for applications requiring 100 per cent welding and/or grinding without removing the pipe clamp. Each jackbar comes with a pivot pad, allowing this pipeline welding clamp to be used on coated or uneven pipe surfaces.

A step by step guide to using the Sawyer Rim Clamp

Watch this short video for a quick explanation of how to use Sawyer’s Rim Clamp.

The setup process for the Rim Clamp is engineered to save time and protect equipment:

- Unlock and position the clamp: Release the clamp’s locking mechanism by pulling on its chain-operated hook. Once open, lift the clamp onto the pipe. Smaller 4-12 inch units can be placed manually, while larger sizes require mechanical lifting using the clamp’s built-in lifting chain.

- Center and preset the jackscrews: Before placing the clamp around the pipe, loosen all reforming jackscrews except for the top two. Use the jackscrew setting gauge (provided) to preset these top screws to the approximate pipe radius. This prevents thread damage during installation and ensures the clamp sits true from the start.

- Securing the Clamp: Lower the clamp onto the pipe so that the adjustable jackbars extend approximately 2 inches beyond the pipe ends. As the clamp closes, the locking hook should auto‑latch. If it doesn’t, push the two sides inward until latched securely.

- Align and level the pipe: Use the reforming jackscrews to center the clamp within ±1 inch. Then adjust the stable jackbars until the clamp is perfectly perpendicular to the pipe axis. Slight tweaks to the reforming screws may be required during this step.

- Fitting a secondary pipe or fitting: To align a secondary pipe or fitting, remove the latch pins on the top adjustable jackbars and swing them upward and clear of the joint. This allows full access for alignment and welding prep before reforming pressure is applied.

- Reforming the pipe: Once the two are roughly aligned, begin tightening only the reforming jackscrews over the pipe’s high‑spot and directly opposite (180° apart), working in sequences of three jackscrews. Don’t use all the jackscrews. Avoid overtightening—only apply enough pressure to reform the pipe incrementally. A back-and-forth tightening process (tightening and relaxing) may be needed to bring the pipe back to true round without overstressing the material.

- Release the jackscrews: Once the pipe has been reformed, loosen the jackscrews over the high spot, working in a sequence of three jackscrews. It will be necessary to reduce the pressure of some jackscrews as you tighten others. It may be necessary to repeat this procedure several times.

Take on the toughest pipeline reforming jobs

From placement to reforming, the Sawyer Rim Clamp provides a systematic way to correct ovality and achieve precise line‑up for pipeline welding. Its durable frame, calibrated jackscrews, and thoughtfully designed tools—like the setting gauge and torque wrench—make it a trusted choice for jobs where accuracy is critical.

Not sure the Rim Clamp is the right pipe clamp for you?

Sawyer Manufacturing’s line of pipe-to-pipe fit-up equipment provides a good range of durable, simple, easy-to-use and accurate pipe clamps to meet different needs. Find the right pipe clamp for your specific needs here.

To learn more about Sawyer’s rim clamps and other products, contact the Tremco Pipeline Equipment team at sales@tremcopipeline.com.au or call 07 3344 1066.

As a long-time Host Sponsor, we know a thing of two about surviving – and thriving – at the Australian pipeline industry’s most prestigious event.

Being held at the Brisbane Convention and Exhibition Centre from 18-21 October 2025, the Australian Pipelines and Gas Association (APGA) Convention and Exhibition is the ultimate mix of high-vis expertise, technical deep dives, and good old-fashioned industry banter.

Whether you’re a first-timer still figuring out the difference between a pig and a pig launcher, or a seasoned attendee with a well-worn Gala Night tux, here are Tremco Pipeline Equipment’s essential dos and don’ts to help you make the most of Brisbane this October.

✅ Do: Pack your business cards – and your best handshake

QR codes are great, but a physical card with your name on it is harder to forget (and makes a handy coaster at the bar). You’ll meet everyone from gas policy buffs to field operation veterans. Make connections, swap cards, and remember: nothing says “I’m serious about networking” like a firm handshake and a question that shows you’re interested in learning more.

❎ Don’t: Skip the business sessions

The social events are legendary but the daytime business sessions are where the real gems are shared. The technical papers and policy discussions are one of the best ways to stay up to date with the latest in operations, research and regulation – from gas policy debates to real-world lessons from recent projects.

If you miss the 9am sessions, don’t worry. Someone will happily inform you at lunch that they were “the best ones yet”.

One not to miss: the ZEVAC team will be presenting on closed vent compression systems. They will cover best practices for managing pipeline emissions during pigging, maintenance, and repair operations, plus how ZEVAC’s portable compression equipment is helping operators reduce venting and stay ahead of regulatory and environmental expectations.

✅ Do: Go all-in on Fancy Dress Night

APGA’s themed costume parties are the stuff of industry legend. If you’re not dressed up, you’ll stand out – and not in a good way. Bonus tip: don’t underestimate Brisbane’s humidity and choose breathable fabrics. The hotel aircon may be icy, but step outside and that full-body nylon jumpsuit won’t seem like such a good idea.

❎ Don’t: Be the one who talks shop at the Gala Dinner

There’s a time for compressor specs, and there’s a time for cutting shapes on the dance floor. Know the difference. If you try to discuss hydrotest procedures over dessert, someone will gently guide you toward the bar – for everyone’s sake. Key business relationships are forged at APGA’s social events, but not because you’ve cornered someone into a 30-minute sales pitch.

✅ Do: Visit stands 8, 9 and 10 to tap into international expertise

With David Henry from Girard Industries, Guz Garza Jr from CRC Evans, and Doug Sahm from ZEVAC, you’ve got a global brains trust at your disposal.

Whether it’s how to progressively pig your pipeline, avoid venting during maintenance, or align your welding system in the middle of nowhere – chances are, our global experts have solved it. Use your time at the stand to dive deep into technical solutions with people who live and breathe this stuff.

The Tremco Pipeline Equipment team will be on hand throughout the exhibition to demonstrate equipment, discuss product solutions, and catch up with customers and industry peers.

❎ Don’t: Underestimate the massage booth

Yes, it’s real. Yes, it’s free. And yes, after a day on the exhibition floor (or night on the dance floor), it will change your life.

Brought to you by Tremco Pipeline Equipment because we care about your lower back almost as much as your pipeline integrity. Remember: prevention is better than a cure. We’re basically offering free physio.

✅ Do: Pace yourself at the social events

APGA’s iconic social events bring fun and connection to the convention experience, and Tremco Pipeline Equipment is proud to co-sponsor the Exhibition Opening, Fancy Dress Dinner and the Gala Dinner.

But be warned: four nights of back-to-back social events require pacing. You don’t want to peak too early – and you definitely don’t want to try to keep up with someone from WA at the bar. You will lose. They’ve trained for this.

❎ Don’t: Forget to follow up post-convention

You’ll have dozens of great chats – in sessions, at the booth, over satay skewers. Don’t let those leads and learnings fade away after you return to your desk. Follow it up on LinkedIn or email, and lock in the next step. The real value is what happens after the event. You can contact the Tremco Pipeline Equipment team at sales@tremcopipeline.com.au

The 2025 Australian Pipelines and Gas Association (APGA) Convention and Exhibition is being held at the Brisbane Convention and Exhibition Centre from 18-21 October 2025. Visit Tremco Pipeline Equipment at Stands 8, 9 & 10 to connect with all international guests and explore technical solutions first-hand.

The ONIS Quick Action Line Blind provides a safe, efficient, and easy-to-maintain solution for isolating pipelines during maintenance and inspection. With spreading technology and external seals, it reduces downtime, simplifies maintenance, and eliminates the need for complex disassembly or specialised tools.

Why positive isolation matters in pipeline safety

Isolating equipment for maintenance and inspection is crucial for ensuring pipeline safety and functionality. Positive isolation (or blinding activities) stops hazardous materials from entering a section of pipeline required to be shut down for maintenance, allowing workers to perform tasks safely while avoiding disruption to the rest of the pipeline system.

Traditional line blinds often require shutdowns, disassembly, and specialised equipment to maintain—leading to costly delays. The ONIS Quick Action Line Blind offers a modern alternative that simplifies the process and enhances operational efficiency.

What sets the ONIS Quick Action Line Blind apart?

The key difference in ONIS technology lies in its design.

Traditional Line Blinds

- Rely on non-spreading mechanisms with internal components.

- Internal seals are difficult to reach and replace.

- Maintenance requires full pipeline shutdowns and disassembly.

- Often involves cranes and heavy machinery.

ONIS Quick Action Line Blind

- Uses spreading technology, eliminating internal release mechanisms.

- Seals are external and easily accessible.

- Maintenance can be performed without pipeline shutdowns.

- No special tools or heavy equipment required.

This design reduces downtime, simplifies operation, and lowers costs for pipeline operators.

How to use the Quick Action Line Blind

Operation is straightforward and user-friendly:

- Actuation – Two forged half-bodies are actuated by a lever or hand wheel connected to a gearbox.

- Flange spreading – Synchronised eccentric shafts generate the spreading movement.

- Slide gate positioning – The slide gate moves into a full bore or blind position.

- Clamping – Reversing the lever or hand wheel locks the mechanism.

The clamping system is self-locking, resistant to overpressure and vibration, and factory-tested for reliability.

The equipment is factory-set and tested, eliminating the need for on-site adjustments after installation or operation.

Watch how it works

Simplified maintenance with external seals

One of the biggest advantages of ONIS Quick Action Line Blinds is their simplified maintenance process:

- Only four seals (two online, two offline).

- All seals are located externally for easy access.

- Seals can be replaced without pipeline shutdowns.

- No cranes or heavy equipment required.

- Typical replacement: once a year or when damaged.

This accessibility makes ONIS ideal for industries where extended shutdowns lead to high costs and production delays.

Key advantages over competitor line blinds

| Feature | ONIS Quick Action Line Blind | Traditional Line Blinds |

| Technology | Spreading design | Non-spreading internal mechanisms |

| Seal Access | External, easy to replace | Internal, difficult to access |

| Downtime | Minimal, no shutdown required | Requires shutdowns |

| Maintenance | Simple, no special tools required | Complex, heavy machinery often required |

| Reliability | Self-locking, vibration-resistant | Prone to wear and difficult to adjust |

Tried and tested isolation technology

ONIS, a French manufacturer with 40+ years of expertise, is the only provider of proven Quick Action Line Blinds for high-pressure applications. Their design combines reliability with operational efficiency, making it the preferred solution for industries including oil, gas, and petrochemicals.

By choosing ONIS, pipeline operators benefit from:

- Enhanced safety through positive isolation.

- Reduced downtime and faster maintenance.

- Long-term reliability in harsh operating conditions.

The ONIS Quick Action Line Blind offers a smarter way to achieve pipeline isolation during maintenance and inspection. With its spreading technology, external seals, and quick-action clamping system, ONIS helps operators save time, reduce costs, and improve safety.

Tremco Pipeline Equipment is the Australian, NZ and PNG agent for ONIS products. For more information, contact Brett Trembath on (07) 3344 1066 or email sales@tremcopipeline.com.au

CRC Evans’ DATA360 platform is transforming pipeline construction projects with advanced digital data management for onshore and offshore infrastructure.

What is DATA360?

DATA360 is CRC Evans’ flagship digital platform, designed to streamline infrastructure and energy projects by providing end-to-end lifecycle data management. From pipe manufacturing to final installation—whether laid in the ditch onshore or submerged offshore—DATA360 creates a digital footprint for every pipe joint using a unique identifier.

This innovation solves one of the pipeline industry’s biggest challenges – fragmented systems and siloed information.

DATA360 delivers a true cradle-to-grave digital record by consolidating critical workflows such as welding, coating, NDT, material traceability, and AI-powered fitment analysis.

Why digital data management matters in pipeline construction

Traditional pipeline projects often rely on multiple disconnected systems, slowing down compliance checks and increasing the risk of costly errors. DATA360 eliminates this by creating a cradle-to-grave digital record, allowing contractors, owner-operators, and inspection companies to:

- Improve compliance and traceability

- Enhance efficiency and reduce downtime

- Cut costs with streamlined workflows

- Access real-time project data anytime, anywhere.

CRC Evans Vice President of Engineering and Technology Shailesh Radhakrishnan says: “Traditionally, collecting and analysing data from a construction project can take hours each day. Our new digital platform can do this within a few minutes – making the process a lot more efficient. Contractors can access tailored production data anytime, anywhere, without additional time for data processing.”

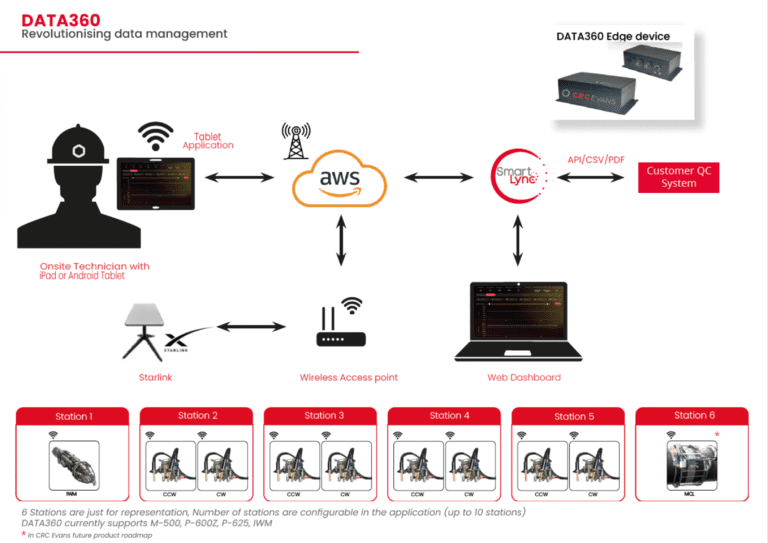

How DATA360 works?

Powered by cloud computing and centralised storage, the DATA360 platform enables stakeholders—from pipe mills to NDT companies—to securely log and access critical production data.

Key features include:

- IoT integration: Collects data from welding and coating systems with GPS tracking and long-range Wi-Fi.

- Satellite connectivity: Ensures data visibility even in remote offshore environments.

- AI analysis: Uses clustering algorithms and fitment analysis to optimise welding operations.

- Geospatial visualisation: Provides an intuitive, location-based view of pipeline activity.

This creates a connected pipeline ecosystem that supports faster decision-making and proactive quality control.

User-friendly web and mobile interfaces

At the heart of DATA360 is a user-centric interface thoughtfully designed for web and mobile platforms:

Mobile App: Optimised for field inspectors, welders, and supervisors with offline functionality and simplified data capture.

Web Dashboard: Offers real-time reporting, advanced filtering, and powerful data visualisation for project managers.

Together, these platforms bridge the gap between field operations and project management, improving collaboration across teams.

Case study: 9,000-joint welding project compliance streamlined with DATA360

In 2023-24, Van Oord used DATA360 as a data and joint ID monitoring system for an Exxon gas pipeline located offshore Guyana. The project consisted of over 9,000 joints and had strict compliance requirements.

To prevent pipeline failure, it was critical to keep the hardness of the material in contact with the medium (ID pipe and root pass) below 248 HV10. This meant the heat input must be 100 percent verified to maintain the hardness levels and stay within the welder performance qualifications (WPQ).

DATA360 was used to:

- Monitor the end-to-end welding for all stations;

- Track data for specific joints against unique joint IDs; and,

- Supply Exxon with hard copies of the data as proof of compliance.

The system provided a log record for each joint as evidence that the completed welds were within the boundaries of the welding procedure specification (WPS) and thus fit for purpose from a mechanical point of view.

Benefits for CRC Evans and Its clients

DATA360 not only supports clients but also drives internal efficiency at CRC Evans.

At the Kintore facility in Scotland, engineers use DATA360 for:

- Fast retrieval of welding data and reports

- Real-time analysis for quality verification

- Post-production insights to improve future projects

Kintore Senior Welding Engineer Melina Hemery says she finds DATA360 a powerful tool that saves her team considerable time on documentation, data capitalisation and problem solving.

“It allows us to quickly retrieve welding data, available in the form of a customisable “as-run” report. These reports, obtained in record time, allow us to verify that all welding parameters are correct and therefore guarantee the quality of the welds.”

Hemery says that she uses the system before, during, and after production:

- Before: by verifying our welding parameters during procedure development

- During: to confirm the expected quality and provide the data to third parties and customers

- After: to analyse data, improve procedures for specific applications, and use them on future projects.

For Kintore’s Senior R&D Lead, Stephen Cameron, DATA360 has transformed the way he approaches his research: “I can pull graphs from any weld that is in process or complete. It gives me a great visual aid to assess how the machines are performing. It lets me hone in on any potential issues before they arise, which ultimately leads to improving weld quality.

“DATA360 has really made my life easier and is now a permanent tool on all equipment in our facility in Kintore,” says Cameron.

A legacy of innovation in pipeline construction

For 90 years, CRC-Evans has been a leader in pipeline construction equipment, automatic welding systems, managed subsea services, field joint coating and heat treatment, and non-destructive testing.

With DATA360, CRC Evans continues this tradition by delivering digital solutions that increase efficiency, compliance, and performance.

Radhakrishnan says that the company understands the importance of continually evolving its products to meet current market needs: “Our aim is to deliver innovation and operational efficiency. The DATA360 does just that.”

CRC Evans Director, Digital Transformation Vinay Baburao couldn’t agree more: “We’re committed to developing advanced digital products and solutions like DATA360 to meet the evolving needs of our clients. Leveraging DATA360 allows users to streamline operations, enhance decision-making, and boost overall business performance.”

Based in Houston, Texas, CRC-Evans has offices in North America, Europe, South Africa and the Middle East. CRC Evans’ products are available through Oceania via its exclusive agent, Tremco Pipeline Equipment.

For more information, email sales@tremcopipeline.com.au or visit www.tremcopipeline.com.au

From cleaning to geometry measurement to tracking and launching, Tremco Pipeline Equipment has got you covered.

Pigging is a crucial aspect of maintaining the integrity of pipelines. Tremco Pipeline Equipment distributes leading international utility pig and cleaning pig brands to the Oceania market, each designed to address specific pipeline challenges quickly and effectively.

Cleaning pigs: Girard Industries

As manufacturer of the original ‘Polly-Pig’, Girard Industries has been producing high-quality pipeline cleaning pigs and accessories for over 55 years.

At the forefront of innovation in pipeline cleaning, Girard makes and provides technical assistance on pigs to clean even the most difficult natural gas, hydrocarbon, water and special application pipelines, with all equipment manufactured at its plant in Houston, Texas.

Its product catalogue includes poly-pigs (or foam pigs), steel mandrels, solid cast polyurethane, polyurethane spheres and pig tracking equipment for both pipeline and meter proving applications, as well as replacement cups, discs and other urethane wear parts to fit most pigs on the market.

Tremco Pipeline Equipment has partnered with Girard to distribute its pigs and equipment in Australia for over 25 years. It carries a range of foam and cast urethane pigs in stock from 1-20 inches, and works with clients on custom pig designs and orders for pipelines that are considered unpiggable.

Batch, separate or evacuate: Maloney pipeline spheres

Maloney Technical Products’ manufactured the first pipeline sphere in 1952, and remains the industry leader in spheres to separate and batch products, or for meter proving and pipeline evacuation activities. The spheres can also be used as signal actuating devices.

Maloney spheres are specially designed with a thick wall, and compounded for optimum resiliency. The spheres are compression-moulded at cavity pressure exceeding 2000 PSI – a process that is critical to ensuring a uniform density of the compounded material to yield unmatched wear-resistance.

The spheres can pass through short bends, properly designed tees and full-opening conduit type valves. They can pass through out-of-round pipe, will wear evenly, and can be wear-compensated by adjusting the diameter by inflation.

Recently, Maloney Technical Products collaborated with CDI to introduce the Maloney Smart Sphere – a trackable pipeline sphere capable of withstanding rugged pipeline conditions without any abnormal wear and tear.

The Smart Sphere carries a transmitter that lets you track its location and speed. It features quick and easy transmitter removal and replacement, two ports for normal inflation and filling, and is available in a variety of polymers and sizes.

Maloney’s spheres are available for order from Tremco Pipeline Equipment as required.

Real-time cleaning pig tracking: made easier with CDI

Established in 1982, CDI brings innovation and reliability to pipeline pig tracking.

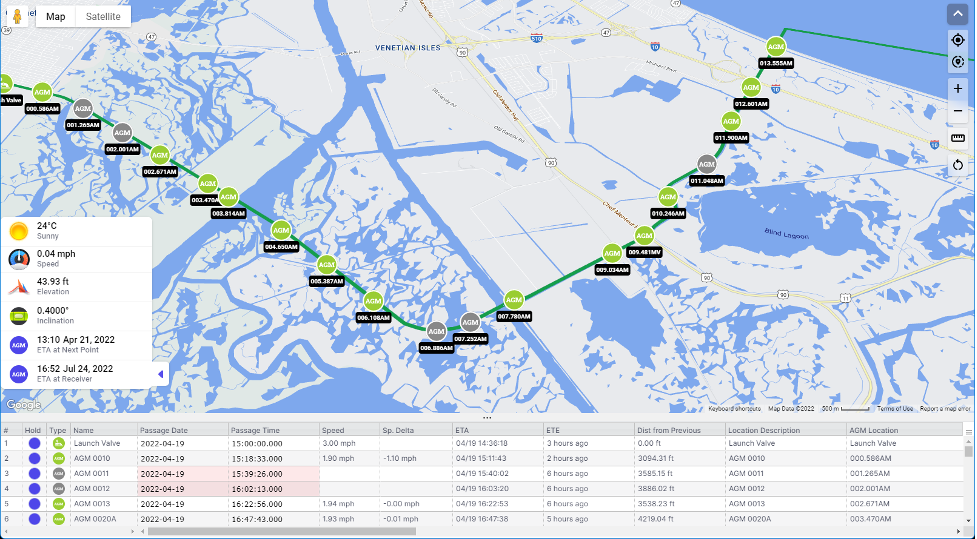

The company’s Qube Above Ground Marker (AGM) and GlobalTrack Cloud Service has redefined pig tracking by providing seamless real-time monitoring and data accessibility for pipeline cleaning operations.

The Qube AGM accurately detects the passages of pipeline pigs equipped with MFL magnetisers and EM transmitters, and can track pigs acoustically with its built-in geophone. The GlobalTrack cloud connectivity works with the Qube AGM to enable stakeholders from anywhere in the world monitor pipeline pig progress in real-time, either manually or through automated tracking.

The products also streamline data transfer and reporting processes. With automatic data uploads to the GlobalTrack cloud service, manual downloads are no longer necessary, and run reports become available as soon as the tool is trapped. This saves time and resources while providing valuable insights for decision-making.

Alternatively, CDI’s PigAlert and PigAlert Pro pig tracking tools are a cost-effective solution which magnetically attach to a pipeline asset. The tools offer real-time text message notifications, GPS tracking, and no monthly fees. Both tools detect magnet-equipped pipeline pigs, but PigAlert Pro adds the ability to detect flags tripping and switch closures from intrusive pig signalers.

Both devices are available with an optional remote and wireless flasher indicator with a magnetic base, allowing for convenient remote monitoring of pig passages. PigAlert and PigAlert Pro are durable and waterproof, making them the reliable and straightforward choice for pig tracking.

Tremco Pipeline Equipment also distributes a range of CDI EM transmitters and tracking receivers.

Some CDI tracking equipment is kept in stock, while other pieces can be ordered for fast delivery.

Pigging valves and accessories for efficient pig transfer, launching and receiving

Tremco Pipeline Equipment distributes a range of pipeline pigging valves and accessories, which can be ordered in to suit your specific application. These include BKW sealing and non-sealing pig switches and Cactus Flow Product shut-off pig valves.

The BKW switches are robust, low-maintenance piggable diverter valves specially designed to allow efficient, non-obstructed product transfer.

Cactus Flow Product shut-off pig valves are a special type of ball valve made in Texas that allows the launch and receipt of pigs, without the use of a pig launching system. This makes them a more economical and environmentally safe option compared to traditional pig launches.

The bi-directional valves are available in sizes between 2 and 12 inches in either RF and RTJ connections and are compatible with special Girard pigs. The valves feature a fire-safe design, manufactured with a forged body and stainless-steel trim.

Inquire now

To find out more about the pipeline pigging equipment manufacturers and products that Tremco Pipeline Equipment represents, stocks and distributes, contact the team on (07) 33441066 or sales@tremcopipeline.com.au

The Sypris Sig-Tech Intrusive Pig Signaler is a proven, durable, and easy-to-install solution for detecting pig passage during pipeline maintenance and operations. It delivers real-time confirmation, supports emissionless pigging, and reduces downtime across onshore and offshore projects.

The Sig-Tech signalers are used to detect the real-time passage of pigs within a pipeline, supporting operators with real-time confirmation and helping verify run success. Designed for ease of installation and long-term durability, the Sig-Tech units are suitable for both onshore and offshore applications, and can be installed under live conditions with the correct tools.

How the Sig-Tech Intrusive Pig Signaler works

Installed at predetermined intervals along the pipeline, the Sig-Tech intrusive pig signaler detects the movement of cast polyurethane pigs or spherical type pigs. A trigger mechanism extends into the pipeline through a welded boss fitting. When a pig passes, it activates the trigger, which sets off a signaling mechanism, confirming the pig’s position and supporting real-time operational decision-making.

This signal provides confirmation of the pig’s passage, helping operators verify pig locations, monitor run success, and identify any potential obstructions or failures in real-time.

Designed for flexibility and ease of use

The Sig-Tech is easy to install, with each boss fitting designed to the correct intrusion depth based on wall thickness requirements. A flanged mounting option is also available if required. The signaller can be installed and removed under operating pressure, acting in a similar way to a pressure and equalisation fitting completion plug.

Once installed, the signaler requires no further calibration or adjustment – offering a plug-and-play solution.

The 3705 PSI (Class 1500#) design is compatible with other leading brands, which makes it a flexible option for both newly constructed pipelines and system upgrades. In addition, using the appropriate tools and procedures, the signaller can be installed on live pipelines, avoiding the need for costly shutdowns.

The Sig-Tech’s stainless steel NACE MR0175 compliant construction is weather and corrosion-resistant, ensuring durability and performance in extreme environments, including offshore and remote installations.

Multiple indication options

Sypris offers a range of signaling mechanisms to suit different operational needs:

- Mechanical Flag Indicator for visual confirmation in the field

- Electrical Indicator for remote monitoring via integration with SCADA or control systems

- Combination Flag/Electrical Indicator for redundant and versatile signaling

Sypris’ electrical versions include a 316SS electrical switch as standard, in addition to providing excellent corrosion resistance and a long service life.

No calibration required

One of the key benefits of the Sig-Tech is its maintenance-free design. Once installed, no further adjustments or calibrations are needed. The welded boss fitting is set to the correct intrusion depth based on pipeline wall thickness and is designed to ensure accurate alignment with the pig path.

A reliable addition to your pigging toolkit

By providing accurate, real-time pig passage confirmation, the Sig-Tech Intrusive Pig Signaler helps operators:

- Maintain pipeline efficiency

- Reduce downtime and shutdown costs

- Improve safety and compliance

- Operate effectively in demanding conditions

When paired with Girard polyurethane pigs and ZEVAC emissionless pigging equipment, the Sig-Tech offers a complete, environmentally responsible pigging solution.

Tremco Pipeline Equipment Director Brett Trembath said: “Our range supports emissionless pigging. The Girard poly pigs and the Sig-Tech pig signaller can be used in conjunction with our ZEVAC equipment so no venting is required during pigging operations.”

For more information on the Sypris Sig-Tech Intrusive Pig Signaler, or other pigging products supplied by Tremco Pipeline Equipment, contact Brett Trembath (07) 3344 1066 or email sales@tremcopipeline.com.au

Hydrogen’s unique properties demand a shift in how the pipeline industry approaches maintenance and repair.

“Old Mates: Gone but Never Forgotten,” is a sincere and heartfelt documentary by Sunshine Coast filmmaker and TV personality, Rob Brough, featuring Ron Trembath and his surf lifesaving group.

Nothing tears at the heartstrings more than the imagery of thousands of boats rowing into the shore of Anzac Cove to the tune of trumpets blasting the Last Post.

CDI is redefining pipeline pig tracking by pairing pig tracking equipment with cloud-based software to deliver easy access to real-time data, alerts and detailed reports for pipeline inspection and cleaning operations.

Margaret was the loving and devoted wife of Ron, sister of Christine and David, mother of Brett and Lisa, nanny of Ayden and Kyla, a friend to many, and the backbone of Tremco Pipeline Equipment for many years.

In the world of oil and gas, downtime can be costly, and safety is a top priority. That’s why Tremco Pipeline Equipment has partnered with ONIS to supply innovative, safe solutions for quick pipe opening operations to the Australian market.

Confused about which external pipe clamp is the best to purchase for your pipeline welding needs? Tremco Pipeline Equipment and Sawyer Manufacturing outline pipe clamp basics and give you all the information you need to find the right pipe clamp for your job, including a handy cheat sheet.

An exclusive partnership between Tremco Pipeline Equipment and PLIDCO (The Pipeline Development Company), stretching back to the turn of the century, continues to supply the local market with industry leading pipeline repair fittings.

As manufacturer of the original ‘Polly-Pig’, Girard Industries has been producing high-quality pipeline cleaning pigs and accessories for over 55 years. We spoke with Girard general manager Michael Henry about the changes he’s seen in the pipeline industry, and his top tips for a successful pipeline cleaning program.

ZEVAC’s new methane emission reduction technology has an ambitious goal to significantly reduce methane emissions in the ongoing battle against climate change.