Pipe Clamp 101: how to find the best external pipe clamp for your pipeline needs

Confused about which external pipe clamp is the best to purchase for your pipeline welding needs? Tremco Pipeline Equipment and Sawyer Manufacturing outline pipe clamp basics and give you all the information you need to find the right pipe clamp for your job, including a handy cheat sheet.

Through a long-standing partnership of over 20 years, Tremco Pipeline Equipment supplies 12 types of durable and hard-wearing Sawyer Manufacturing external pipe clamps to the Oceania pipeline market. Each is suited to specific applications, including small or large diameter pipe, alignment or reforming, tack or no tack, and clamps with hydraulic or hand lever mechanisms. But how do you know which external pipe clamp is the most suitable for your needs?

To make the process easier, Tremco Pipeline Equipment and Sawyer Manufacturing have teamed up to explain the basics of pipe clamps, and demystify which clamps are best suited to specific applications.

What is a pipe clamp?

A pipe clamp is a circular or semicircular metal attachment that fits tightly around the pipeline and connects it to a pipe hanger assembly. The clamp is used to secure, align or reform the pipe while completing pipeline welding during construction or maintenance activities.

How do pipe clamps work?

The best pipe clamps are made with a simple structure that can be easily and quickly fitted around the pipe. For welding, pipe alignment clamps keep the pipe aligned and restrained while the welding process is completed. They help to keep welding pressure steady, increase welding accuracy, and reduce the risk of weld failure due to stress, misalignment or lack of pressure.

External clamps can also be used to reform pipe to aid accurate and efficient welding for out-of-round pipe. Also known as pipe ovality, this can occur during the transportation of new high-strength steel, thin-walled pipe, or on existing pipelines that have been subject to adverse weather conditions or buried for a long period of time.

Types of pipe clamp

There’s a large range of different external pipe clamps available for specific needs. At Tremco Pipeline Equipment, we supply Sawyer Manufacturing cage clamps, rim clamps, hydraulic clamps, and easy-to-use, efficient clamps for small diameter pipelines. Sawyer’s line of pipe-to-pipe fit-up equipment is simple, easy to use, durable and enables accurate welding.

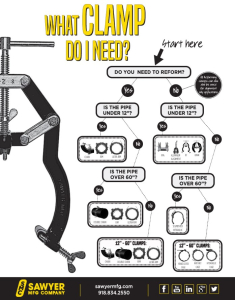

So which pipe clamp is best? Sawyer Manufacturing has put together this quick quiz to help you decide on the right pipe clamp for your job.

Pipe under 12 inches, no reforming required

The best external pipe clamps for small diameter pipelines where the pipe hasn’t lost its shape are Sawyer’s:

- Precision Pipe Alignment (PPA) Clamp

- Aluminium Alignment Clamp

- External EZ Clamp.

The Sawyer PPA Clamp is a fabrication clamp, perfect for alignment for small diameter thin wall pipes, with quality weld accuracy on pipes up to Schedule 20. The PPA clamp jaws work independently to allow pipes to be concentrically aligned regardless of their diameters. These lineup clamps are designed to be compatible with all leading Orbital Welding Heads. Made from high-purity stainless steel, the PPA clamps won’t contaminate stainless steel pipes.

If convenience, speed and versatility are key, Sawyer’s portable Aluminium Alignment Clamp (also called a donut clamp) has a two-piece, light-weight design that allows welders to achieve full 360-degree welding. The clamp is made for speed and ease of use – one person can position the clamp and start welding in about two minutes for most applications and pipe sizes. Constructed of high-strength cast aluminium alloy, the clamp is precision bored to ensure accurate alignment and pipe-to-pipe fit up. It’s available in ¾ inch through to 6 inch sizes, and sizes are also available for special tubing.

Sawyer’s External EZ Clamp can be used and attached with ease on nearly any material, including stainless steel, various alloys and plastics. It easily attaches to align pipes, flanges, elbows, and reducers. For even greater adaptability, this lightweight but field-tough fence clamp is built with wing nut screws that allow it to easily adjust to any specific pipe clamp requirement, quickly and accurately attaching with instant centering. The EZ clamp comes in four different models, servicing pipe diameters from 1 inch to 12 inches.

The easy-to-use tack-type Qwik Clamp is available in three sizes to align small diameter pipe from 1-12 inches. The simple design means that no special training is required to operate the clamp and its lightweight body enables the clamp to be used in environments where space is restricted. These clamps can be used to align pipe to pipe, pipe to tee, pipe to flange or pipe to fitting and can also be used with a Hi-Lo Gauge and Spacing Wedge. It’s suitable for use on stainless steel pipes without the need for extra shoes or screws.

Pipe between 12-60 inches, no reforming required

Sawyer’s cage clamps are the best type of clamps to use on pipe between 12-60 inches in diameter where no reforming is required. Tremco Pipeline Equipment supplies three types of cage clamps:

- Hand lever cage clamp

- Ratchet cage clamp

- Hydraulic cage clamp.

Sawyer’s easy and efficient Hand Lever Cage Clamp has been industry standard for over 50 years. It uses a manual toggle to align pipe through to Schedule 80. Each clamp fits one specific pipe diameter from 2 inches to 60 inches. Jack Screw Wedges and Hi-Lo Wedges are optional accessories that give this clamp even greater versatility.

If speed, simplicity and strength are required, Sawyer’s External Ratchet Cage Clamp (shown in the featured image of this post) is a good option. The quality, steel ratchet mechanism provides extra strength to align large diameter pipe, and makes this clamp one of the most dependable pipe alignment clamp options available. Each clamp is hinged for easy placement on the pipe and is available in a tack or no-tack style. Flat, tack-style crossbars are flared to easily position pipes; the clamp must be removed after the tack weld to finish welding. Arched no-tack bars can increase quality and efficiency by allowing full 360-degree welding without removing the clamp.

Or, if you need a pipe clamp with a bit more power, Sawyer’s Hydraulic Cage Clamp pulls tight on with minimal effort, and once welding is complete, the hydraulic cage clamp mechanism enables rapid release of the clamp. The no-tack design of this alignment clamp features arched cross bars for 360-degree welding access without removing the clamp. The Hydraulic Clamp is available for pipe sizes between 16 and 60 inches.

Pipe over 48 inches, no reforming required

As the largest clamp on the market, the heavy duty Segmented Hydraulic Clamp handles pipe-to-pipe fit up jobs on pipe diameters over 48 inches. To allow greater flexibility and enhance the handling of large diameter pipe, the heavy duty Segmented Hydraulic Clamp features a double ring construction with relieved webs and hinged segments, making it a useful tool for pipe tie-in, take up and relay or anomaly digs.

Reforming required – Chain Clamps

Sawyer’s Chain Clamp is more or less a one-size-fits-all clamp, offering pipe-to-pipe fit-up and alignment from pipe 4-72 inches in diameter. This clamp can reform pipe up to Schedule 40 and align pipe up to Schedule 80, yet its lightweight construction also makes it an easy-to-use and easy-to-transport external line up clamp. The Sawyer Chain Clamp can also be used as a single jackscrew clamp. One Chain Clamp can do the job of many bulky cage clamps, saving time and money when needing an adjustable pipe clamp.

When more muscle is needed, the Double Chain Clamp is designed for aligning and reforming pipes and vessels as large as 6 metres (20 feet) in diameter and up to Schedule 80. If no reforming is required, the clamps can be used to align pipes over Schedule 80. The clamps feature specialised heavy duty jack bars and main blocks to deal with even the most difficult of reforming jobs. The adaptable jackscrews permit proper alignment of tees, elbows, or flanges, and they can be welded without removing the clamp.

Each Double Chain Clamp is supplied with a torque wrench set to ensure the correct pressure (150 mm) is applied to the chain, unlike hydraulic systems that risk stretching the chain and/or applying too much pressure to the pipe, risking the integrity of the clamp. The clamps can be supplied with an optional level and support device or a pull lift (come along) for larger pipes if required.

Reforming required – Rim Clamps

The Rim Clamp is designed to take on some of the toughest reforming jobs in the pipeline industry. The clamp provides a viable alternative to the Double Chain Clamp for users who prefer an external line up clamp with a rigid shell.

Sawyer’s manual lineup Rim Clamp is designed for use on out-of-round pipes that require a high level of alignment accuracy. The Rim Clamp will reform 45,000 PSI tensile strength pipe up to Schedule 80, with out-of-round conditions up to 2 inches (51 mm) depending on wall thickness. The clamps feature heavy duty, galvanised jackscrews with pivoting pads and a jackscrew setting gauge that makes initial setup easy while ensuring accuracy and reliability.

Much like the Rim Clamp, the Sawyer Ultra Rim Clamp is designed for use on out-of-round pipes requiring a high level of alignment accuracy, but the Ultra Rim Clamp is a heftier pipeline welding clamp than the previous model and is built to align and reform X65, X70, and X80 pipe. It’s capable of reforming pipe with an out-of-round condition of up to 2 inches (51 mm). Multiple jackscrews give the user the ability to apply precise reforming pressure on specific areas of pipe. The specialised torque wrench supplied with the clamp furthers this capability by allowing the user to set the exact torque required for the reforming application, saving time and effort by setting the perimeter of the jackscrews before the external line up clamp is placed on the pipe. The unique jackscrews are trapezoidal, which are stronger than conventional jackscrews and can assert more pressure to the pipe.

The hinged flip-up jackbars on the Ultra Rim Clamp allow for simple pipe mating, and also ensure the clamp can be used for applications requiring 100 per cent welding and/or grinding without removing the pipe clamp. Each heavy duty jackbar also comes with a pivot pad, allowing this pipeline welding clamp to be used on coated or uneven pipe surfaces. The pivot points of this pipe clamp are made from stainless steel so one clamp will work for all pipe applications, eliminating the potential for pipe contamination.

The Ultra Rim is available in a range of sizes to accommodate pipe sizes from 4 inches to 72 inches.

Comprehensive line of pipe-to-pipe fit-up pipe clamps

Sawyer Manufacturing’s line of pipe-to-pipe fit-up equipment provides a good range of durable, simple, easy-to-use and accurate pipe clamps to meet your particular needs.

If you have any questions about the best pipe clamps for your unique needs, talk to the team at Tremco Pipeline Equipment at sales@tremcopipeline.com.au or call 07 3344 1066.