PetroSleeve

The patented PETROSLEEVE® is the only permanent, non-intrusive pipe repair system that can be installed in 1 hour without interrupting operations.

Clients have saved millions of dollars on pipeline repairs in the USA, Canada, Australia, France, Mexico, Dominican Republic and Papua New Guinea on pipes ranging from 3″ to 48″. The PETROSLEEVE® exceeds code requirements, and as of 2024 over 50,000 installations have been completed without reported failure.

The PETROSLEEVE® and can be installed, ready to be coated and backfilled in just 1 hour.

The PETROSLEEVE® comes with complimentary EIP Analysis and Documentation Software, and is a simple repair method that can be completed regardless of weather conditions or user expertise.

The PETROSLEEVE® can repair wide range of defects on any type of pipeline, such as natural gas, sour gas, crude oil, high vapor products, and refined products..

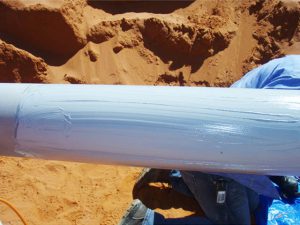

The PETROSLEEVE® is a permanent, non-intrusive Repair System that is easy for any crew to perform. The carrier pipe is cleaned, epoxy applied, PETROSLEEVE® assembled and compressed, and then the PETROSLEEVE® is welded together… all in about an hour.

Quality Assurance: The PETROSLEEVE® is tested and validated as a permanent pipe repair. The PETROSLEEVE® is the only pipe repair, short of defect removal, that repairs cracking, and it does not require welding to the pipeline. Additionally, each PETROSLEEVE® installation is verified using quality control procedures in association with our complimentary Analysis/Documentation EIP software. The PETROSLEEVE®:

- Maintains constant compression on the carrier pipe and never disbonds from the pipeline

- Permanently restores the integrity of the pipe

- Alleviates concerns related to high CE, thin wall, and high strength steels (X70+) that are difficult to in-service weld

- Installs in all weather conditions

- Permanently repairs defects, arresting any defect growth

- Interference fit ensures steel to steel contact, which will allow the pipeline’s corrosion protection system (e.g. cathodic protection) to also protect the PETROSLEEVE®

How It Works – Defect Repair Details

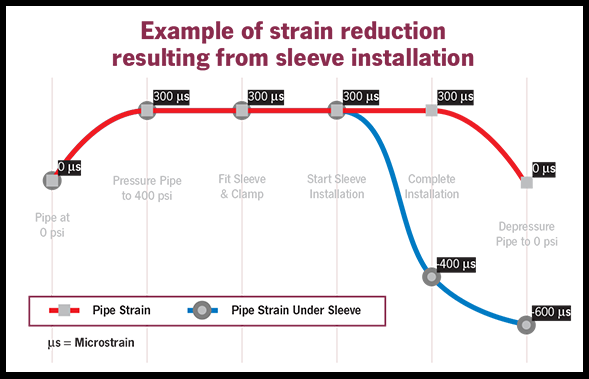

The PETROSLEEVE® successfully applies compressive forces to both the pipe and the defect. First, the sleeve’s compressive forces contain the expansion of the pipe under pressure. Second, the sleeve’s compressive forces place the repair area into compression for all operating ranges. Simply put, an installed PETROSLEEVE® keeps the pipeline in a compressive state, eliminating any possibility of defect failure. A PETROSLEEVE® installation:

- Reinforces the pipeline defect area, essentially creating a heavy wall section

- Ensures that defects (even Stress Concentrator defects) cannot grow

- Overcomes pipeline expansion from pipeline operational forces

- Prevents separation between the PETROSLEEVE® and pipeline within all pipeline operating ranges. The pipe and PETROSLEEVE® move and act as a single unit.

- Transfers stress from the pipe to the PETROSLEEVE®

- Confirms integrity of the repair through reporting, QA and site validation

The PETROSLEEVE® delivers defect repair for Seam or Pipe Body Cracking, Corrosion, Dents, Mechanical Defects, SCC (Stress Corrosion Cracking), Manufacturing Defects, and Arc Burns. Although the failure mechanism varies for each defect type, the following provides a general overview of how the PETROSLEEVE® permanently removes the respective failure mechanisms:

Epoxy

PETROSLEEVE® Inc. has now received the updated epoxy MSDS sheets for 2013.The product manufacturer did a complete MSDS analysis of the epoxy which has resulted in some significant positive changes to the product MSDS information. Particularly, the epoxy is no longer considered dangerous goods for shipping. This is particularly significant for air transportation; however, does have savings when shipping by ground or sea as well. The epoxy specifications and technical data remain unchanged.

Epoxy packaging & mixing ratio

The packaging will still consist of two parts, Part A and Part B. The Part A is shipped in a container that has the capacity to hold the entire contents of both Parts A & B. You only are required to transfer all of Part B into the Part A container and commence mixing. Neither Part A nor B is considered Dangerous Goods for transportation purposes. Although the epoxy is no longer considered dangerous goods for Transportation, please remember to read, understand and follow all information provided on PETROSLEEVE® epoxy MSDS sheets.

Clamping

Specially designed tools such as clamps to ensure an appropriate installation every time.

Small Diameter Sleeve Clamps (Less than 30″ Diameter)

Used to clamp small diameter sleeves in position during installation.

Large Diameter Sleeve Clamps (30″ Diameter and Greater)

Used to clamp large diameter sleeves in position during installation.

Heating

Heating the Petrosleeve

– For sizes up to 28″ it is done with 4 x LPG hand held heater torches

– For 30″ and up a heater cradle is used along with the hand held torches. They are size specific.

Welding

Welding of Petrosleeve to itself to complete the installation.

Installation Complete

The PETROSLEEVE® installation is easy to learn and easy to teach others. The PETROSLEEVE® is a non-intrusive repair system that is easy for any crew to perform.

- There is no welding to the carrier pipe.

- Free EIP(Engineering Installation Parameter) Software calculates, records and confirms stress conditions of each installation.

Installation Kit

Each PETROSLEEVE® comes with an installation kit which contains the epoxy mixing tools, and cleanup tools necessary during installation.

Hoist Bars (Less than 30″ Diameter)

Comes in a set of two and assists in raising the lower half of the PETROSLEEVE® into position.

Hoist Cradle (Greater than 30″ Diameter)

The Hoist Cradle comes as a unit and assists in raising the lower half of a large diameter PETROSLEEVE® into position when the half can not be managed by hand.