Blog

23 Year Partnership Still Delivering Industry Leading Fittings to Local Market

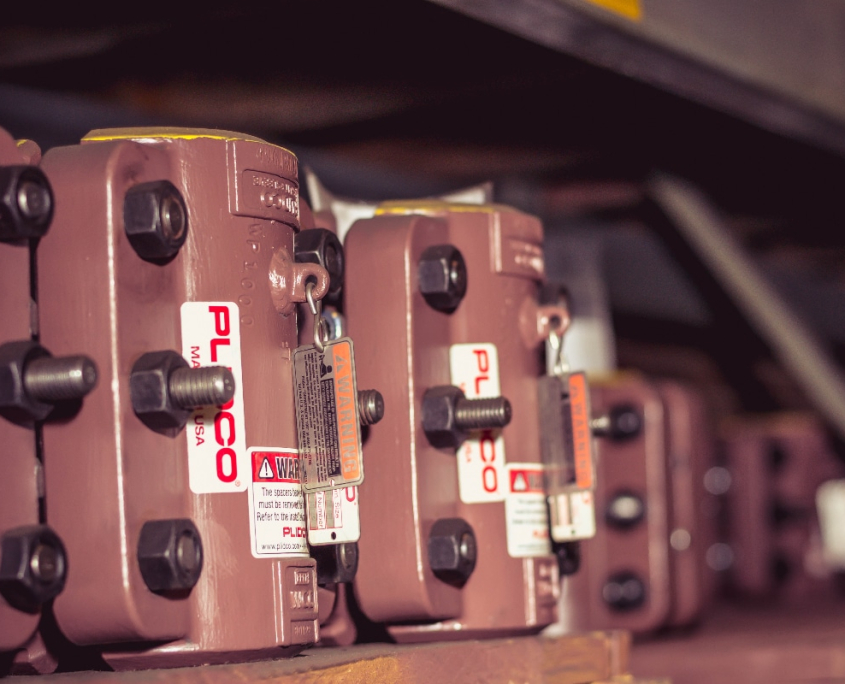

An exclusive partnership between Tremco Pipeline Equipment and PLIDCO (The Pipeline Development Company), stretching back to the turn of the century, continues to supply the local market with industry leading fittings.

PLIDCO manufactures high quality pipeline repair and maintenance products worldwide, including to the local market through the partnership with Tremco Pipeline Equipment.

The manufacturer is particularly well-renowned in Australia and the Oceania region as a result of the exclusive partnership, established in 2000, which facilitates Tremco Pipeline Equipment supplying quality pipeline fittings to the local market.

Notably, Tremco Pipeline Equipment supplied the three 42-inch Queensland Curtis LNG, Australia Pacific LNG and Gladstone LNG pipelines with PLIDCO split sleeves between 2012 and 2014.

“Every pipeline owner and operator in Australia, New Zealand and Papua New Guinea trusts PLIDCO’s leak repair fittings and keeps these fittings in their emergency response and maintenance stores,” said Tremco Pipeline Equipment Director and Sales and Service Technician Brett Trembath.

An industry leader for nearly 75 years, PLIDCO’s products are used for high pressure emergency repairs and routine maintenance, both onshore and subsea.

The company’s products are versatile – with applications ranging from oil, gas and water to chemical, steam and slurry piping systems.

Invented by PLIDCO and copied by many, the company’s products are designed and manufactured in line with a strict quality control program.

The innovative pipeline fittings help ensure safe repairs and reliable installations while preventing or minimising costly shutdowns.

PLIDCO is ISO 9001 certified and does not use any material sourced from China, India or Korea.

The company’s products come with the pipeline industry’s only five-year warranty which – along with PLIDCO’s reputation for providing world-class products – guarantees customers have reliable products and a positive experience.

“Manufacturers have to be doing something right to be in business for more than 70 years,” said Trembath.

“PLIDCO’s hundreds of thousands of fitting installations is testament to its standing in the industry, both in Australia, New Zealand, PNG and the Pacific, and around the world.”

For more information call +61 7 3344 1066 or visit the Tremco Pipeline Equipment website.

Cleaning pig tips from the original ‘Polly-Pig’ manufacturer, Girard Industries

As manufacturer of the original ‘Polly-Pig’, Girard Industries has been producing high-quality pipeline cleaning pigs and accessories for over 55 years. Tremco Pipeline Equipment spoke with Girard general manager Michael Henry about the changes he’s seen in the pipeline industry, and his top tips for a successful pipeline cleaning program.

In 1958, Harry Girard supplied the first polyurethane foam cylinders to a California oil company to remove moisture and debris in natural gas pipelines. Following the success of the cleaning run, Girard refined a range of patented coatings and geometrical shapes that became recognised throughout the pipeline industry as the ‘Polly-Pig’.

Since then, Girard Industries has been at the forefront of innovation in pipeline cleaning, batching and gauging pigs, developing new products to meet the demands of a changing industry.

General manager Michael Henry, who has been with Girard for over 17 years, reflected on the way the industry has changed.

“Pigs have become more commonplace in the lexicon of the pipeline industry,” Henry said.

“It was not long ago, when I first started attending conferences, I’d receive the weirdest looks and comments about our products. People would come up, stare, maybe touch a pig in our booth, similar to someone seeing a pig at a petting zoo for the first time.”

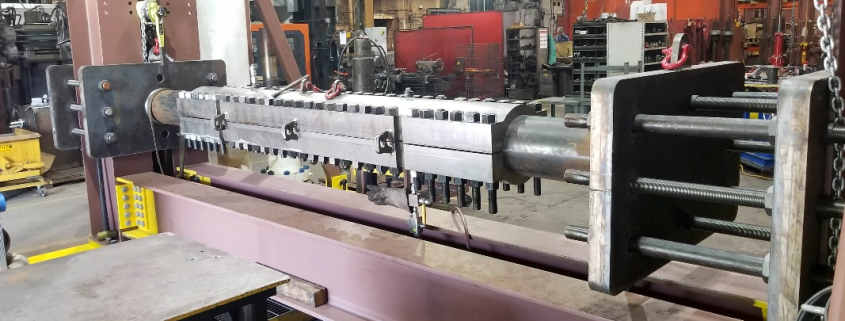

Today, the team at Girard makes and provides technical assistance on pigs to clean even the most difficult natural gas, hydrocarbon, water and special application pipelines, with all equipment manufactured at its plant in Houston, Texas.

Its product catalogue includes polly-pigs (or foam pigs), steel mandrels, solid cast polyurethane, polyurethane spheres and pig tracking equipment for both pipeline and meter proving applications, as well as replacement cups, discs and other urethane wear parts to fit most pigs on the market.

Girard’s top tips for a successful pipeline cleaning program

Henry has two pieces of advice for Australian pipeline operators maintaining the integrity of their pipelines.

- Be proactive with your pipeline cleaning“No truer words have been spoken than the old adage: ‘an ounce of prevention is worth a pound of cure’,” Henry said. “Cleaning a pipeline doesn’t just have to be when you shut the line down. Routine maintenance – as little as running a single pig a week – could be what keeps problems from forming.”

- Don’t rush the pigging process

“Problems happen when pigging is rushed,” Henry noted. “This occurs when personnel want it completed faster or with fewer pigs.”

Henry explained that the pigging equivalent of the saying ‘walk before you run’ is ‘swab before you brush’.

“There are many reasons to run swabs or other less aggressive pigs before a true cleaning pig, and all these reasons help to avoid major problems.”

A long-standing Australian partnership built on trust

For more than 25 years, Girard Industries has partnered with Tremco Pipeline Equipment to distribute its pigs and equipment in Australia.

“During this time, we’ve seen how much customers trust Tremco Pipeline Equipment and that’s because they strive to truly solve problems and not just sell products,” Henry said.

“They’re not afraid to suggest a solution that is substantially less expensive than what the customer wants. The team at Tremco Pipeline Equipment helps to maintain integrity in pipelines, as well as holding it as a core value at a company level.”

For more information about the right cleaning, batching or gauging pig to meet your needs, contact Brett Trembath at brett@tremcopipeline.com.au

Tremco Pipeline Equipment Adds Methane Emission Reduction Technology to its Product Range

Queensland based Tremco Pipeline Equipment Pty Ltd has added TPE Midstream and their new ZEVAC technology to reduce methane emissions to its already extensive product range for the Australian, New Zealand and PNG Pipeline Industries.

The new technology has an ambitious goal to significantly reduce methane emissions in the ongoing battle against climate change.

The technology is currently being used on a pipeline project in Trumbull county, USA by Dominion Energy who is conducting pipeline maintenance and valve replacement work at a site just outside Newton Falls.

Usually, to do that work would require evacuating or clearing the line by venting methane gas into the atmosphere.

Instead, new technology allows them to clear the line using Zero Emissions Vacuum and Compression or ZEVAC to capture methane and re-cycled it back into the system.

“We’re using portable compressors to evacuate that gas and re-inject it downstream,” said Project Supervisor Gina Rundo.

The process represents significant savings compared to venting. “Thirteen million cubic feet is the metric that we will be saving from avoiding that 18 miles of gas that would have traditionally been vented into the atmosphere,” Rundo said.

This industry-leading technology is a significant investment on Dominion’s part.

“We’ve spent a couple of million dollars on this project alone to maintain that gas in the system,” said Dominion’s Rick Kawiecki Dominion Energy has set a lofty goal to reduce methane emissions across its entire system.

“Our end goal is to reduce our methane emissions by fifty percent by 2030, and with this technology it allows us to support that effort,” Rundo said.

Dominion says that’s the equivalent of planting 250 million new trees or taking 3.3 million cars off the road for a year. Methane is a potent greenhouse gas; it has 25 times more global warming potential than carbon dioxide.

For more information on this new technology contact Tremco Pipeline Equipment at sales@tremcopipeline.com.au or call 07 3344 1066 or visit www.tremcopipeline.com.au