As a long-time Host Sponsor, we know a thing of two about surviving – and thriving – at the Australian pipeline industry’s most prestigious event.

Being held at the Brisbane Convention and Exhibition Centre from 18-21 October 2025, the Australian Pipelines and Gas Association (APGA) Convention and Exhibition is the ultimate mix of high-vis expertise, technical deep dives, and good old-fashioned industry banter.

Whether you’re a first-timer still figuring out the difference between a pig and a pig launcher, or a seasoned attendee with a well-worn Gala Night tux, here are Tremco Pipeline Equipment’s essential dos and don’ts to help you make the most of Brisbane this October.

✅ Do: Pack your business cards – and your best handshake

QR codes are great, but a physical card with your name on it is harder to forget (and makes a handy coaster at the bar). You’ll meet everyone from gas policy buffs to field operation veterans. Make connections, swap cards, and remember: nothing says “I’m serious about networking” like a firm handshake and a question that shows you’re interested in learning more.

❎ Don’t: Skip the business sessions

The social events are legendary but the daytime business sessions are where the real gems are shared. The technical papers and policy discussions are one of the best ways to stay up to date with the latest in operations, research and regulation – from gas policy debates to real-world lessons from recent projects.

If you miss the 9am sessions, don’t worry. Someone will happily inform you at lunch that they were “the best ones yet”.

One not to miss: the ZEVAC team will be presenting on closed vent compression systems. They will cover best practices for managing pipeline emissions during pigging, maintenance, and repair operations, plus how ZEVAC’s portable compression equipment is helping operators reduce venting and stay ahead of regulatory and environmental expectations.

✅ Do: Go all-in on Fancy Dress Night

APGA’s themed costume parties are the stuff of industry legend. If you’re not dressed up, you’ll stand out – and not in a good way. Bonus tip: don’t underestimate Brisbane’s humidity and choose breathable fabrics. The hotel aircon may be icy, but step outside and that full-body nylon jumpsuit won’t seem like such a good idea.

❎ Don’t: Be the one who talks shop at the Gala Dinner

There’s a time for compressor specs, and there’s a time for cutting shapes on the dance floor. Know the difference. If you try to discuss hydrotest procedures over dessert, someone will gently guide you toward the bar – for everyone’s sake. Key business relationships are forged at APGA’s social events, but not because you’ve cornered someone into a 30-minute sales pitch.

✅ Do: Visit stands 8, 9 and 10 to tap into international expertise

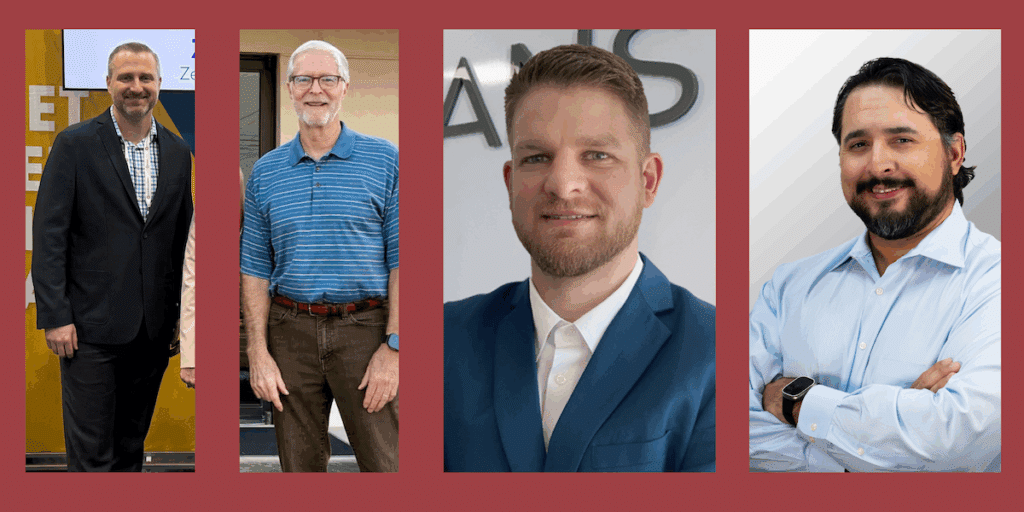

With David Henry from Girard Industries, Guz Garza Jr from CRC Evans, and Doug Sahm from ZEVAC, you’ve got a global brains trust at your disposal.

Whether it’s how to progressively pig your pipeline, avoid venting during maintenance, or align your welding system in the middle of nowhere – chances are, our global experts have solved it. Use your time at the stand to dive deep into technical solutions with people who live and breathe this stuff.

The Tremco Pipeline Equipment team will be on hand throughout the exhibition to demonstrate equipment, discuss product solutions, and catch up with customers and industry peers.

❎ Don’t: Underestimate the massage booth

Yes, it’s real. Yes, it’s free. And yes, after a day on the exhibition floor (or night on the dance floor), it will change your life.

Brought to you by Tremco Pipeline Equipment because we care about your lower back almost as much as your pipeline integrity. Remember: prevention is better than a cure. We’re basically offering free physio.

✅ Do: Pace yourself at the social events

APGA’s iconic social events bring fun and connection to the convention experience, and Tremco Pipeline Equipment is proud to co-sponsor the Exhibition Opening, Fancy Dress Dinner and the Gala Dinner.

But be warned: four nights of back-to-back social events require pacing. You don’t want to peak too early – and you definitely don’t want to try to keep up with someone from WA at the bar. You will lose. They’ve trained for this.

❎ Don’t: Forget to follow up post-convention

You’ll have dozens of great chats – in sessions, at the booth, over satay skewers. Don’t let those leads and learnings fade away after you return to your desk. Follow it up on LinkedIn or email, and lock in the next step. The real value is what happens after the event. You can contact the Tremco Pipeline Equipment team at sales@tremcopipeline.com.au