Pipeline project data: how to tag, collect and analyse construction data within minutes

CRC Evans’ DATA360 platform is transforming pipeline construction projects with advanced digital data management for onshore and offshore infrastructure.

What is DATA360?

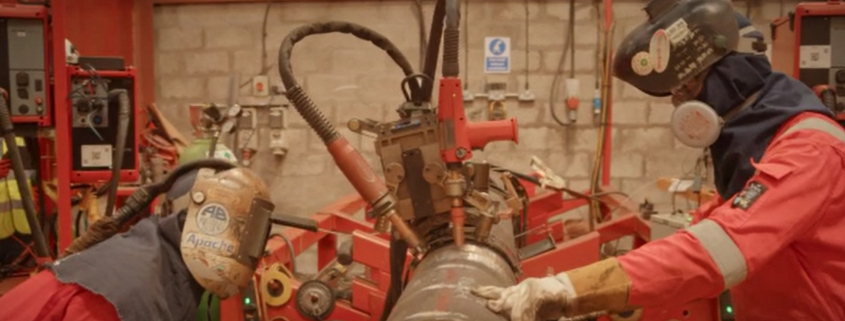

DATA360 is CRC Evans’ flagship digital platform, designed to streamline infrastructure and energy projects by providing end-to-end lifecycle data management. From pipe manufacturing to final installation—whether laid in the ditch onshore or submerged offshore—DATA360 creates a digital footprint for every pipe joint using a unique identifier.

This innovation solves one of the pipeline industry’s biggest challenges – fragmented systems and siloed information.

DATA360 delivers a true cradle-to-grave digital record by consolidating critical workflows such as welding, coating, NDT, material traceability, and AI-powered fitment analysis.

Why digital data management matters in pipeline construction

Traditional pipeline projects often rely on multiple disconnected systems, slowing down compliance checks and increasing the risk of costly errors. DATA360 eliminates this by creating a cradle-to-grave digital record, allowing contractors, owner-operators, and inspection companies to:

- Improve compliance and traceability

- Enhance efficiency and reduce downtime

- Cut costs with streamlined workflows

- Access real-time project data anytime, anywhere.

CRC Evans Vice President of Engineering and Technology Shailesh Radhakrishnan says: “Traditionally, collecting and analysing data from a construction project can take hours each day. Our new digital platform can do this within a few minutes – making the process a lot more efficient. Contractors can access tailored production data anytime, anywhere, without additional time for data processing.”

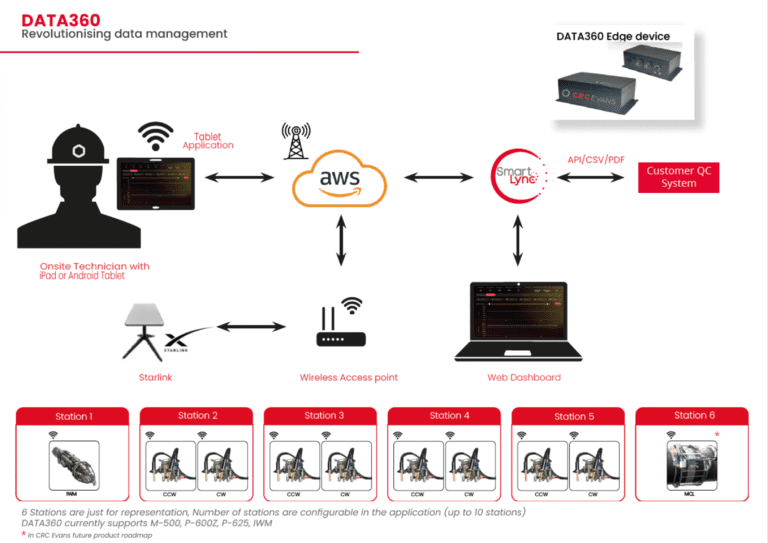

How DATA360 works?

Powered by cloud computing and centralised storage, the DATA360 platform enables stakeholders—from pipe mills to NDT companies—to securely log and access critical production data.

Key features include:

- IoT integration: Collects data from welding and coating systems with GPS tracking and long-range Wi-Fi.

- Satellite connectivity: Ensures data visibility even in remote offshore environments.

- AI analysis: Uses clustering algorithms and fitment analysis to optimise welding operations.

- Geospatial visualisation: Provides an intuitive, location-based view of pipeline activity.

This creates a connected pipeline ecosystem that supports faster decision-making and proactive quality control.

User-friendly web and mobile interfaces

At the heart of DATA360 is a user-centric interface thoughtfully designed for web and mobile platforms:

Mobile App: Optimised for field inspectors, welders, and supervisors with offline functionality and simplified data capture.

Web Dashboard: Offers real-time reporting, advanced filtering, and powerful data visualisation for project managers.

Together, these platforms bridge the gap between field operations and project management, improving collaboration across teams.

Case study: 9,000-joint welding project compliance streamlined with DATA360

In 2023-24, Van Oord used DATA360 as a data and joint ID monitoring system for an Exxon gas pipeline located offshore Guyana. The project consisted of over 9,000 joints and had strict compliance requirements.

To prevent pipeline failure, it was critical to keep the hardness of the material in contact with the medium (ID pipe and root pass) below 248 HV10. This meant the heat input must be 100 percent verified to maintain the hardness levels and stay within the welder performance qualifications (WPQ).

DATA360 was used to:

- Monitor the end-to-end welding for all stations;

- Track data for specific joints against unique joint IDs; and,

- Supply Exxon with hard copies of the data as proof of compliance.

The system provided a log record for each joint as evidence that the completed welds were within the boundaries of the welding procedure specification (WPS) and thus fit for purpose from a mechanical point of view.

Benefits for CRC Evans and Its clients

DATA360 not only supports clients but also drives internal efficiency at CRC Evans.

At the Kintore facility in Scotland, engineers use DATA360 for:

- Fast retrieval of welding data and reports

- Real-time analysis for quality verification

- Post-production insights to improve future projects

Kintore Senior Welding Engineer Melina Hemery says she finds DATA360 a powerful tool that saves her team considerable time on documentation, data capitalisation and problem solving.

“It allows us to quickly retrieve welding data, available in the form of a customisable “as-run” report. These reports, obtained in record time, allow us to verify that all welding parameters are correct and therefore guarantee the quality of the welds.”

Hemery says that she uses the system before, during, and after production:

- Before: by verifying our welding parameters during procedure development

- During: to confirm the expected quality and provide the data to third parties and customers

- After: to analyse data, improve procedures for specific applications, and use them on future projects.

For Kintore’s Senior R&D Lead, Stephen Cameron, DATA360 has transformed the way he approaches his research: “I can pull graphs from any weld that is in process or complete. It gives me a great visual aid to assess how the machines are performing. It lets me hone in on any potential issues before they arise, which ultimately leads to improving weld quality.

“DATA360 has really made my life easier and is now a permanent tool on all equipment in our facility in Kintore,” says Cameron.

A legacy of innovation in pipeline construction

For 90 years, CRC-Evans has been a leader in pipeline construction equipment, automatic welding systems, managed subsea services, field joint coating and heat treatment, and non-destructive testing.

With DATA360, CRC Evans continues this tradition by delivering digital solutions that increase efficiency, compliance, and performance.

Radhakrishnan says that the company understands the importance of continually evolving its products to meet current market needs: “Our aim is to deliver innovation and operational efficiency. The DATA360 does just that.”

CRC Evans Director, Digital Transformation Vinay Baburao couldn’t agree more: “We’re committed to developing advanced digital products and solutions like DATA360 to meet the evolving needs of our clients. Leveraging DATA360 allows users to streamline operations, enhance decision-making, and boost overall business performance.”

Based in Houston, Texas, CRC-Evans has offices in North America, Europe, South Africa and the Middle East. CRC Evans’ products are available through Oceania via its exclusive agent, Tremco Pipeline Equipment.

For more information, email sales@tremcopipeline.com.au or visit www.tremcopipeline.com.au

Leave a Reply

Want to join the discussion?Feel free to contribute!