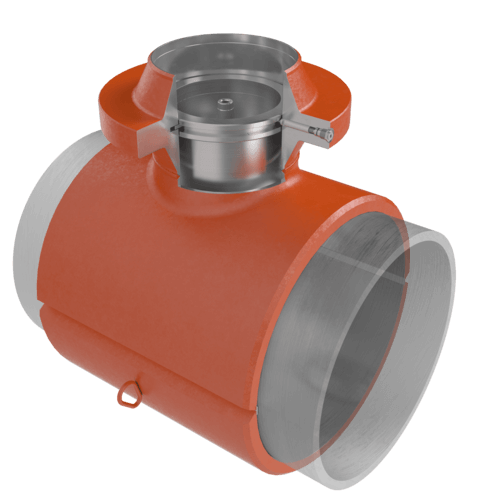

Sureloc Line Stop Tees

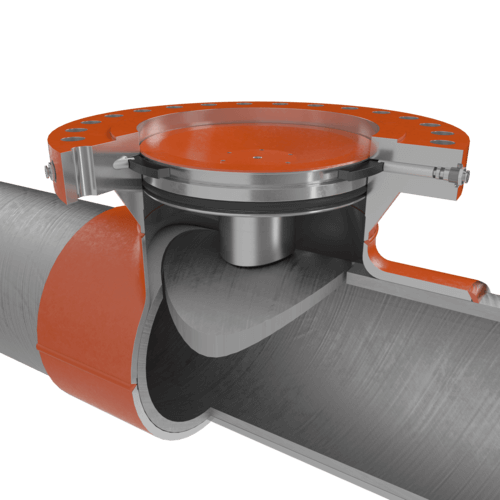

WeldFit’s Sureloc™ line stop fittings are used when the removal of the tapping valve is desirable after the completion of a temporary line stop operation. Once the need for the line stop has ended and the line stop head is removed, the Sureloc™ blind plug is inserted into the Sureloc™ fitting flange and locked into place by extending the segments into a groove in the plug. An O-ring is incorporated into the plug in order to create a leak-proof seal. Once the Sureloc™ blind plug is installed, the tapping equipment can be removed and a blind flange installed to complete the process. If there is a need to reinstall the line stop at a future date, it is normally possible to remove the blind flange and plug, in order to insert the line stop head.

ASME B31.3, B31.4 & B31.8 LINE STOP FITTINGS

WeldFit’s Sureloc™ fittings are fabricated using our extruded outlet tees for branch sizes up to 36″ NPS. There are several advantages to using extruded outlet tees; including the ability to design reinforcement into the nozzle and the elimination of the weld between the header and the branch, which is difficult to radiographically inspect. Above 36″ NPS branch sizes, WeldFit utilizes a fabricated tee. All pressure containing welds of WeldFit’s Sureloc™ Tee are 100% radiographically inspected. Our standard Line Stop Tee fittings are offered for 4″ through 48″ pipe sizes with ASME Class 150, 300, and 600 flanges

Sureloc™ line stop tees are normally supplied with full port size-on-size branch connections suitable for standard line stop operations. However, WeldFit can supply reduced port tees for by-pass applications or for use as hot tap tees when a Sureloc™ Flow-Through Plug will be installed.

In addition to the standard Sureloc™ blind plug, WeldFit can also supply a Sureloc™ scarfed nipple plug or a Sureloc™ Flow-Through Plug when future line pigging is expected. The scarfed nipple plug is used when it is necessary to remove the tapping valve. It incorporates an extension from the bottom of the plug, to which the coupon is welded. Once installed, the coupon covers the tapped hole, which guides the pig past the outlet.

A Sureloc™ Flow-Through Plug is used in a standard hot tap procedure. It ensures product flow through the tapping outlet, but it incorporates bars that guide the pig past the cut hole. A flow-through plug is also commonly called a guide-bar plug.

KEY FEATURES:

- Sureloc™ Flange and Blind Plug allow for retrieval of hot tapping valve upon completion of line stop procedure.

- Sureloc™ Flow-Through (Guide Bar) Plug is available when flow through the outlet is required and the header is subject to future pigging

- Fittings can be supplied to meet ASME B31.3, B31.4, B31.8 or other pipeline design codes.

- Standard fittings available for 4″ through 48″ pipe sizes with ASME Class 150, 300, and 600 flanges

- Larger fittings and higher pressure class flanges are available upon request

- Back-up strips available

- All pressure containing welds are 100% radiographically inspected

- Compatible with industry standard hot tap and line stop equipment and procedures

- Manufactured in compliance with WeldFit’s ISO 9001:2008 certified quality program