ALH – Flowstop

Flowstop Heavy Duty Orange Airbag

System 1 Twin Bagtube

PS/E4 Bags

Flowstop Canvas Covered Airbags

Eesiseel PVC Stopper Bags

CDI

Pigging Signalers

Non-Intrusive Signalers and Accessories

ATEX & IECEx CD52 Bandit

UL & CSA CD52 Bandit

CD52-316SS Stainless Steel

Standard Trip Magnets

CD52-M3

CD52-M0

CD52-M1

CD52-M2

Optional Equipment

Satellite Notification

Flex Cable

EM Transmitters

Traxall Pig Tracking Transmitters – 22Hz and 15-32Hz

N-Cell Transmitters (Very Small)

AA-Cell Transmitters (Small)

C-Cell Transmitters (Mid-Size)

D-Cell Transmitters (Largest)

Pig Tracking Transmitters

T-Series, 22Hz Fixed-Frequency, High Temperature

Tracking Receivers

Traxall Receivers (22hz and Multiple Sources)

Traxall 720

Traxall 770

Traxall 500/501

Traxall 620

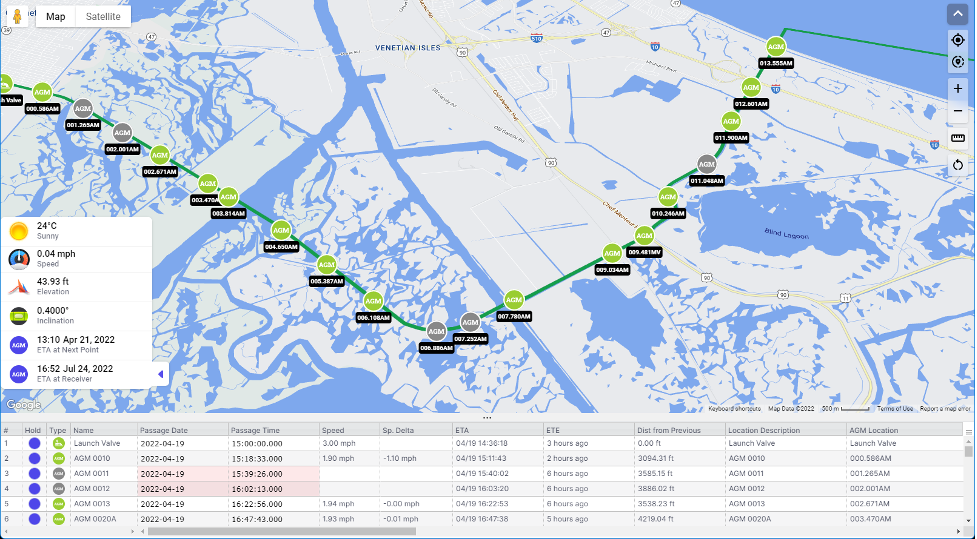

Qube AGM

Pig Alert & Pig Alert Pro

Girard Industries

About Girard Industries

UNMATCHED PERFORMANCE WITH PROVEN RESULTS

MANUFACTURING SUPERIOR PIPELINE CLEANING

SOLUTIONS SINCE 1968

Polly Pigs

Girard Turbo Pigs

Polly Pigs Mandrel Pigs

Pig Tracking

Pig-valve Pigs

Custom Made Pigs

Cups & Discs

Polyurethane Spheres

Petro-Line

About Petro-Line

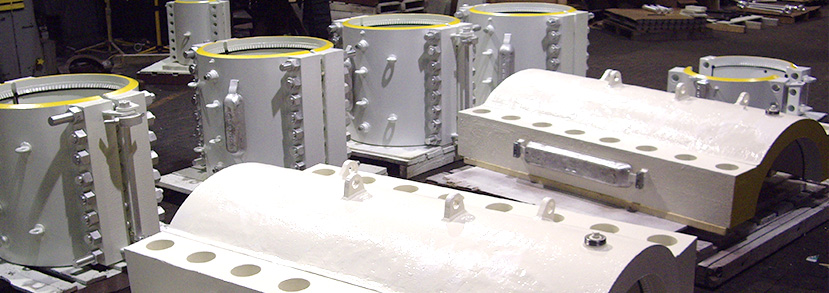

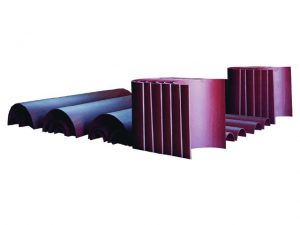

The patented PETROSLEEVE® is the only permanent, non-intrusive pipe repair system that can be installed in 1 hour without interrupting operations.

Clients have saved millions of dollars on pipeline repairs in the USA, Canada, Australia, France, Mexico, Dominican Republic and Papua New Guinea on pipes ranging from 3″ to 48″. The PETROSLEEVE® exceeds code requirements, and as of 2019 over 30,000 installations have been completed without reported failure.

The PETROSLEEVE® and can be installed, ready to be coated and backfilled in just 1 hour.

The PETROSLEEVE® comes with complimentary EIP Analysis and Documentation Software, and is a simple repair method that can be completed regardless of weather conditions or user expertise.

The PETROSLEEVE® can repair wide range of defects on any type of pipeline, such as natural gas, sour gas, crude oil, high vapor products, and refined products..

PETROSLEEVE

Plidco

About Plidco

The leader in pipeline repair fittings since 1949, PLIDCO earns customer loyalty by producing innovative solutions that help minimize costly shutdowns and assure worker safety. With hundreds of thousands of fittings installed around the world, PLIDCO is the number one source for safe, reliable pipeline repair products. Customers trust PLIDCO, as we offer the industry’s only 5-year limited warranty.

Clamp+Rings

Clamp+Sleeves

Flange+Repair Ring

Flange Repair Split+Sleeve

Flanger

Hot Tapping+Saddles

Shear+Plug

Sole+Mates (TYPE B SLEEVES)

Split+Repair Ell

Split+Sleeves – Offshore

Smith+Clamp

Riser Weld+Ends

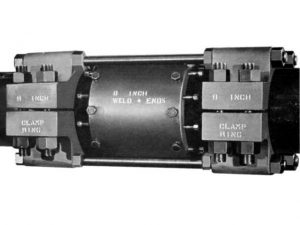

Weld+Ends

Weld+Cap

Split+Sleeve

Weldfit

About Weldfit

WELDFIT HOT TAP FITTINGS FEATURES & BENEFITS

- Size-on-size or reduced branch fittings for use in hot tapping operations

- Supplied with ANSI class 150, 300, 600, 900, or 1500 flanges with raised face or RTJ grooves. Other flange classes available on request.

- Fittings available with a butt weld outlet, ready to be welded to a valve or other fitting

- Standard fittings meet the requirements of ASME B31.3 and ASME B31.4/B31.8

- Fittings with outlets through 48″ NPS utilize extruded outlets, which allows for 100% radiographic examination and eliminates the stress risers inherent in welded type tees

- Compatible with all major models of hot tapping equipment

- All pressure containing welds are 100% radiographed

- Backing strips available

- Manufactured in compliance with WeldFit’s ISO 9001:2015 certified quality program

SureLaunch

SureLaunch

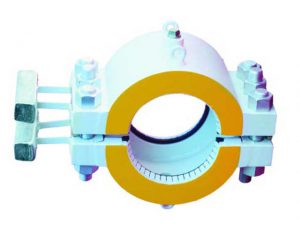

Hot Tap / Line Stop Fitting

Sureloc Line Stop Tees

Purge & Equalization Fittings

ZEVAC

METHANE MITIGATION TECHNOLOGY TO ACHIEVE EMISSION REDUCTION GOALS

ZEVAC is a product and technology company named after our pioneering and patented Zero Emission Vacuum and Compressor units. “ZEVAC®” is an OEM line of portable gas and liquid cross-compression equipment easily integrated into operations and maintenance plans as a safe, reliable, and scalable alternative to natural gas venting and NGL flaring.

Recognized as the industry’s most versatile gas/liquid capture and recovery technology, ZEVAC equipment’s wide range of applications helps the operators that fuel our world and the service contractors supporting them overcome the risk, cost, and compliance challenges of their responsible operating requirements.