12 inch TuffStand

TuffStand — The Gorilla on the Right-of-Way

TuffStand is engineered to be the toughest, safest pipe-stand solution in the oil & gas industry. This single-injection-moulded product uses patent-pending design features and advanced resin technology to bring a new standard of performance.

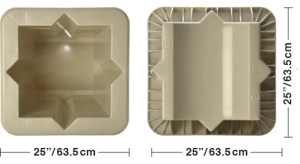

Made from a single injection mold, the DuraPlas TuffStand represents a step forward in pipeline construction technology. Its lightweight yet robust construction uses high-quality, corrosion-resistant materials to deliver a support system that’s easier to handle, reduces freight costs, and lasts far longer than traditional timber skids.

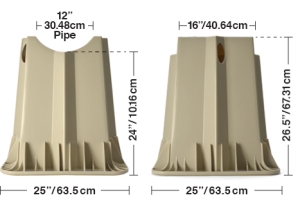

12″ TUFFSTAND: TS12-ST TN

The DuraPlas 12″ TuffStand is designed to be the strongest, safest, and most durable 12″ pipe stand in the oil and gas industry. Utilizing a wide square base and angled side walls, the 12″ TuffStand can withstand the extreme conditions of any pipeline job using 2-12″ pipe. When developing this pipe stand, our goal was to create the absolute best product that provides the safety and efficiency the industry deserves. By replacing a pile of wood skids with the 12″ TuffStand, you are able to increase job efficiency and cut down on the labor costs associated with hauling and moving wood skids. And while wood skids are heavy and often cracked, wet, and rotten, our 12″ TuffStand weighs just 28.5lbs and is made with a high-density polyethylene resin. Make the switch and start using the 12″ TuffStand today!

Why choose TuffStand over traditional timber skids

While timber pipe supports have been used on pipeline construction sites for decades, they can be costly, take time to freight and set up, and pose a safety risk due to their weight and the manual handling required. The DuraPlas TuffStand is engineered to eliminate those issues.

- Built for strength, not decay

Wood breaks down over time — cracking, rotting, or warping when exposed to water, sunlight, and chemicals. TuffStand, on the other hand, is made from single-molded, high-density polyethylene and super-tough nylon, materials that are corrosion-resistant and weatherproof. It maintains structural integrity and stability, even in harsh environments.

- Lightweight yet heavy-duty

Timber skids are cumbersome and heavy to transport and reposition. Each 12 inch TuffStand weighs only 12.9 kg, making it easy for crews to handle and move without machinery, while still supporting impressive loads.

- Enhanced safety and stability

Timber supports can splinter, shift, or collapse under uneven weight distribution. The TuffStand’s wide square base and angled sidewalls deliver superior ground contact and load distribution, reducing the risk of rolling or tipping. That means a safer, more predictable work environment for crews on the ground.

- Consistent and reusable

Every TuffStand is precision-molded for uniform size and strength. Unlike wood, there’s no variability between stands, no nails or bolts to replace, and no risk of hidden weaknesses. After a job is completed, the TuffStands can be reused repeatedly with minimal wear — providing long-term value and less waste.

- Lower total cost of ownership

Factoring in freight, handling, disposal and replacement, timber skids can be expensive. TuffStand’s light weight, long lifespan, and reusability make it a smarter investment that pays off across multiple projects.