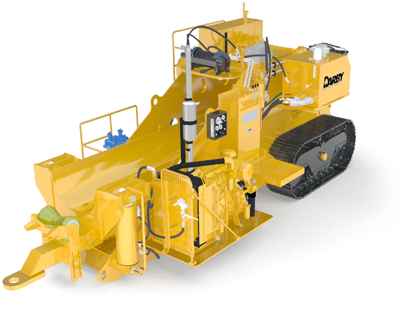

16-30″ Pipe Bending Machine (HPB16-30)

FEATURES AND TECHNICAL SPECIFICATIONS

Features/Advantages:

- 35 gal (133 Litre) fuel tank

- 5 section hydraulic control valve for optionalhydraulic mandrel operation as well as bending operations

- 100 gal (379 Litre) hydraulic tank, 80 gal (303 Litre) fill capacity

- Oil cooler in compressor drive circuit

- Machine side plates reinforced with stiffeners in key locations; Multi-pass welding for optimal frame life and strength; Side plates made from 3/4″ T1 steel; Die nest plates made from 1″ T-1 steel; all welds are pre heated and heat controlled and all welds are made in position

- Dual hydraulic filtration, pressure and return

- Murphy Control panel w/ electric start, throttle control, oil pressure, tachometer and hour meter

- Parker Seal-Lok™ hydraulic systems prevents leaks and has a working pressure rating of 3000 psi

- Repairable hydraulic cylinders with Parker Seals come apart without cutting to enable easy seal repair

- 15 ton CAT style triple grouser tracks

Performance:

- Maximum bending force at front of stiffback 381,700 lbs

- Air compressor with 240 psi maximum continuous pressure

- Hydraulic vane pump for main bending circuit, 42 gpm @ 2400 rpm, 3000 psi

Technical Specifications:

| Length | 22’6″ (4114.8 mm) |

| Width | 8’6″ (2032 mm) |

| Height | 8’6″ (2590.8 mm) |

| Weight | 35,000 lbs (15,876 kg) (w/o bending set) |

| Engine | CAT C4.4 Turbo 109 hp @ 2200 rpm |

| Winch | Ramsey 15,000 lb Winch |

| Air Compressor | Hydraulic Driven Quincy 370 Compressor w/ 120 Gal Reservoir |

| Cylinders | (2) 9″ (229 mm) Outboard Cylinders w/ 19″ Stroke |

| (2) 7″ (178 mm) Inboard Cylinders w/ 6″ Stroke | |

| Hydraulic Pump | Denison Main Pump, Parker Piston Pump for Compressor Drive |

| Oil Cooler | American Industrial |