TPE 2025 year in review: turning industry change into practical progress

Supporting pipeline operators with real-world solutions in 2025.

As the pipeline industry continues to adapt to changing regulatory, environmental, and operational expectations, our focus throughout 2025 remained consistent: supporting pipeline owners and operators with equipment, training, and technical support that works in real-world conditions.

Across the year, our most engaged conversations were about equipment that saves time and improves safety, effective and efficient emissions reduction, and supplier relationships that deliver when it matters.

Strengthening capability through global partnerships

Each year, we attend the Pipeline Pigging and Integrity Management Conference and Exhibition (PPIM) in Houston, Texas. It’s the largest exhibition in the world dedicated to pipeline pigging for maintenance and inspection, engineering assessment, risk management, repair and NDE.

Attending the event allows us to stay across the latest international pipeline maintenance technology and innovation.

We have two main aims at the event. The first is to deepen our understanding of emerging technologies, ensuring the solutions we supply to the Oceania market align with global best practice. The second is to strengthen relationships with our existing partners, many of whom exhibit at the PPIM event, or have offices in the Houston area.

These partners include: Girard Industries, ZEVAC, CDI, PLIDCO, Petroline, In-Line Flow Products, Industrial Degauss, Jireh Inspection Robotics, and WeldFit.

The relationships developed at PPIM underpin our ability to introduce world class equipment locally, supporting pipeline operators and contractors with quality, field-tested solutions.

In 2026, while in the USA for PPIM, we’ll also be attending a PLIDCO meeting and visiting the offices of CRC Evans Auto Weld.

Expanding the product portfolio with purpose

Throughout 2025, we expanded our product offering in response to evolving pipeline industry requirements across construction, maintenance, integrity, and emissions management.

New additions included:

- DuraPlas pipe supports, offering a durable, lightweight and cost-efficient alternative to timber skids

- Hydrogen-compatible PLIDCO fittings designed to resist hydrogen embrittlement and green-marked for easy identification in the field

- Sypris pig signallers, providing real-time, reliable pig passage detection with no calibration required

- CRC Data360, enabling improved capture and management of inspection and construction data by tracking every pipe, every weld, and every joint from mill to installation

- RMA Pipeline Equipment, with hydrogen-compliant monolithic insulation joints (MIJs) and components for CO2 pipelines.

Each addition reflects our focus on providing equipment that improves safety, reliability, and efficiency in the field.

Supporting emissions reduction in operational settings

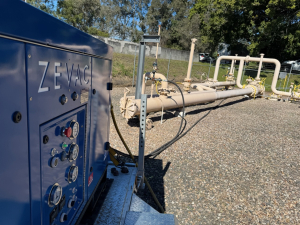

Emissions reduction continues to be a key area of focus for pipeline operators. In 2025, we worked with major Australian pipeline operators to better understand how ZEVAC closed-vent compression systems can be applied across a range of operational scenarios – from pigging and hot tapping to compressor station blowdowns, M&R work, and distribution mains.

At the APGA 2025 Convention and Exhibition, ZEVAC’s Doug Sahm presented a paper outlining 10 practical use cases for ZEVAC’s emissions reduction technology, along with key implementation considerations.

Throughout the year, we worked closely with operator teams to reduce emissions with a focus on safety and no additional downtime:

- Jemena explored the use of ZEVAC to reduce emissions during planned maintenance at the Rolleston Compressor Station. The goal was to measure depressurisation time and assess the impact on schedules. 54.1 GJ of gas was recovered resulting in 29 tCO2e emissions reduction from a depressurisation time of 4 hours and 47 minutes.

- APA Group used the ZEVAC Twin HP unit to reduce emissions during maintenance on a section of pipeline in Brisbane. 14.95 GJ of gas was recovered resulting in 8.02 tCO2e emissions reduction from a depressurisation time of 5 hours and 45 minutes.

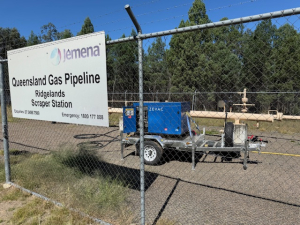

- Zinfra used ZEVAC as part of decommissioning the 25 km, 6 inch Fairview lateral pipeline, recompressing the gas before transferring it to the QGP mainline

- Pro Pipe used ZEVAC on a two-week long emissionless pigging program for AGIG in Victoria.

ZEVAC units are powerful and compact. All units are available for purchase, and a ZEVAC Twin HP unit is also available for hire. In 2025, our hire unit was mounted on a custom trailer with all the required fittings. This ‘hook-it-up and drive-away’ system allows for quick and easy deployment for small to medium drawdown works.

Training to support safe and effective operations

Operator training for both PetroSleeve and PLIDCO pipeline repair methods remained a key component of our support offering in 2025.

Training includes the step-by-step installation process, hands-on practice, troubleshooting potential issues, and full documentation.

While operators hope never to need pipeline repair systems, it’s important to have stock on hand for emergencies – and to have a team that understands how to safely and effectively install the systems. Our aim is to support that readiness.

Building internal capability for the future

In 2025, we expanded our team with the appointment of Dean Bennett as Business Development Manager.

Dean brings nearly three decades of experience in the global pipeline industry, having worked across a range of sales, leadership and technical roles in Australia and Canada. He has a proven track record of fostering long-term relationships with clients, suppliers, and industry partners, and is well-respected across the international pipeline sector.

Dean’s experience, business acumen and understanding of our customer needs will help drive continued growth in the coming years. As demand for specialist equipment and technical support increases, strengthening our team ensures we can continue to provide responsive and informed support to customers.

Over 30 years of industry involvement

We understand that a strong pipeline industry is a connected industry built on long-lasting relationships. For this reason, we participate in as many pipeline industry events as possible. In 2025, we sponsored a number of APGA events, including the Convention, and attended many others throughout the year.

Our commitment to supporting APGA was recognised in 2025 with an APGA Commitment Award. This milestone reflects our long-term involvement in the pipeline industry since Ron Trembath first sponsored the APGA Convention 30 years ago, as well as our ongoing commitment to supporting its development through engagement and collaboration.

Looking ahead

From emissions reduction and training, to new suppliers, major projects, and industry engagement, we enter the year ahead focused on supporting pipeline operators and contractors with equipment, expertise, and relationships they can rely on.

We thank our customers, partners, and suppliers for their trust and collaboration throughout 2025, and look forward to continuing that work in the year ahead.