10 Practical Ways to Reduce Pipeline Venting and Improve Emissions Reduction

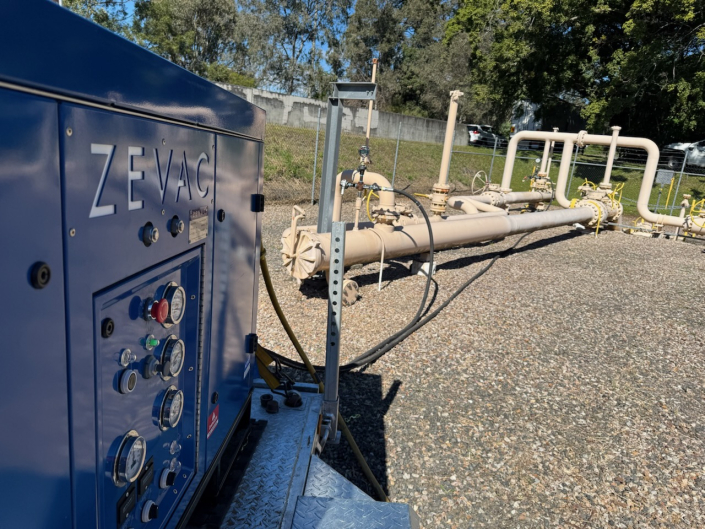

Tremco Pipeline Equipment is helping pipeline owners and operators across Australia, New Zealand and the Pacific Islands reduce their pipeline maintenance emissions with the easy-to-use ZEVAC technology.

Pipeline venting has long been accepted as a necessary part of maintenance. These 10 real-world applications show how closed-vent compression systems support emissions reduction while keeping daily pipeline maintenance efficient and safe.

Across Australia’s transmission and distribution networks, operators are under increasing pressure to minimise methane and VOC emissions while maintaining reliability, safety and community trust.

From pigging to hot tapping to system maintenance, closed-vent compression technology is changing what’s possible in the field. Supplied throughout Oceania by Tremco Pipeline Equipment, ZEVAC systems provide a practical and proven alternative that keeps gas in the system, reducing community impacts, increasing operational control, and providing a better level of safety for crews.

Below is a practical look at how closed-vent compression applies across common pipeline activities, along with the key considerations and benefits for each.

Tremco Pipeline Equipment supplies a ZEVAC unit for hire so operators can achieve emission-less pigging operations.

1. Pigging Operations

Pigging is one of the most common maintenance activities in transmission networks. Each pig run requires venting of both the pig launcher and receiver, and the receiver side often contains liquids and debris.

ZEVAC systems are purpose-built for wet gas and contaminants, allowing crews to recompress the full gas volume safely. Operators can deploy truck-mounted units, trailers, or permanent dP-driven installations where high- and low-pressure piping are co-located. As a result, crews can complete pigging operations without venting, and without exposure to hydrocarbons or contaminants during blowdown.

Benefits

- Eliminates launcher/receiver venting.

- Keeps liquids, NORMs, and debris contained.

Key Considerations

- Launcher blowdowns can be flexible; receiver blowdowns are usually time-critical.

- Consider low-pressure equalisation options for faster cycles.

ATCO has purchased a ZEVAC Mini unit to reduce emissions across its whole value chain.

2. Hot Tapping of Transmission Pipelines

Hot tapping in transmission lines requires multiple depressurisation steps. Closed-vent compression allows each depressurisation – from cutting heads to bypasses – to be performed without atmospheric release. Crews often deploy multiple units to maintain schedule pace.

Benefits

- Full zero-emissions HT&P operations.

- Safer operations without clearing large venting exclusion zones.

Key Considerations

- The timing required for the blowdown.

- Monitor for pressure rebound to confirm true isolation.

- Limited worksite footprints require compact equipment.

Using ZEVAC for routine maintenance: in practice

In 2025, APA Group used the ZEVAC Twin HP unit to reduce emissions during maintenance on a section of pipeline in Brisbane. 14.95 GJ of gas was recovered resulting in 8.02 tCO2e emissions reduction from a depressurisation time of 5 hours and 45 minutes.

Tremco Pipeline Equipment recently worked with Jemena to measure the depressurisation time and impact to schedules when using ZEVAC to reduce venting emissions during planned maintenance at the Rolleston Compressor Station.

3. Compressor Station Blowdowns

Large blowdowns during compressor station maintenance have historically created the highest-volume planned emissions events in transmission systems. Noise and odour from these releases often draw public attention.

Closed-vent blowdown recovery changes the dynamic. By sizing ZEVAC units to match a station’s unique pressures and volumes, operators can recover gas from entire station sections — from quick 15-minute unit resets to multi-hour full-yard drawdowns. Systems can be powered by compressed air, dP, or hydraulic/electric energy.

Benefits

- Eliminates high-volume blowdown emissions.

- Improves restart safety by keeping hydrocarbons contained.

- Reduces noise and community complaints.

Key Considerations

- Understand blowdown timing and urgency.

- Identify suitable discharge and reinjection points. Physical placement can be a challenge if the headers are not in proximity.

- Size equipment according to station volume and pressure ranges.

Compressor station blowdown: in practice

In 2025, Jemena explored the use of ZEVAC to reduce emissions during planned maintenance at the Rolleston Compressor Station. The goal was to measure depressurisation time and assess the impact on schedules. 54.1 GJ of gas was recovered resulting in 29 tCO2e emissions reduction from a depressurisation time of 4 hours and 47 minutes.

4. Compressor Seal Gas Capture

Reciprocating and centrifugal compressors release gas through designed leak paths such as rod packing or dry seals. These small continuous streams contribute surprisingly large annualised emissions.

ZEVAC’s dP-driven ZD3 systems utilise the natural pressure difference between suction and discharge lines to capture seal leakage and reinject it back into the station’s suction side. This method requires no grid power, making it suitable for remote Australian compressor stations.

Operators need to consider allowable backpressure on the seal vents, placement of withdrawal and reinjection points, and whether unit-by-unit or site-wide capture makes most sense.

Benefits

- Captures continuous emission sources (seal vents) 24/7.

- Simplifies compliance with tightening emissions reporting.

Key Considerations

- Confirm allowable backpressure on vent sources.

- Decide between unit-by-unit or site-wide header systems.

- Place reinjection and suction points to optimise flow.

5. Meter & Regulator Station Actuators

Meter and regulator stations frequently use gas-driven actuators that release small volumes of gas with every valve movement. These devices are becoming a focus of operator-led retrofit programs.

Closed-vent solutions offer two approaches: capturing and reinjecting the actuator exhaust gas, or using station differential pressure to generate compressed air for instrument air conversions. Both eliminate pneumatic emissions without requiring full station electrification.

Benefits

- Removes emissions from pneumatic devices.

- Improves control valve performance by tightening deadband.

- Helps to achieve compliance with regulatory pneumatic-device rules.

Key Considerations

- Confirm available dP.

- Evaluate site layout for centralised vs distributed systems.

- Consider air-conversion vs gas-recycling approaches.

6. Meter & Regulator Station Maintenance

During maintenance, station crews routinely isolate and depressurise equipment such as filters, bypasses, valves and meters. Closed-vent compression provides a straightforward alternative: isolate, withdraw, compress and reinject the trapped gas into the upstream or downstream line. The biggest requirement is ensuring that the new workflow is seamlessly integrated into crew standard operating procedures (SOPs).

Benefits

- Aligns leak-reduction culture with maintenance practices.

- Eliminates community disturbance during routine tasks.

- Enhances crew safety.

Key Considerations

- Decide on a permanent site-based solution vs mobile solution.

- Confirm reinjection direction relative to custody meters.

- Validate gas spec and odorisation compatibility.

Tremco Pipeline Equipment offers a compact ZEVAC unit for hire, mounted on a trailer – easy to transport and compact for working onsite with a small footprint.

7. Gas Mains and Distribution Networks

Distribution pipeline networks are constantly undergoing relocations, repairs and upgrades. By connecting a ZEVAC unit to the isolated section and reinjecting the gas back into the live system, operators can evacuate a main quickly (often in less than 30 minutes) without atmospheric release, odour or public disruption.

Benefits

- Eliminates methane and VOC emissions during gas distribution main maintenance

- Improves community relations by eliminating noise and odour issues common during venting

- Improves safety by keeping gas and liquids contained.

Key Considerations Before Implementing

- Identify suitable access points for both evacuation and reinjection.

- Plan around traffic control, citizen proximity, and night-time work constraints.

- Confirm positive isolation to prevent pressure rebound.

Pipeline decommissioning: in practice

In 2025, Zinfra used ZEVAC as part of decommissioning the 25 km, 6 inch Fairview lateral pipeline, recompressing the gas before transferring it to the Queensland Gas Pipeline mainline.

8. Odour Fade and Odourisation Work

Odour fade remains a persistent challenge in distribution networks, particularly in newly commissioned pipelines or sections that experience low flow. Operators often induce flow by venting – a method that creates unnecessary emissions and elevates risk.

Closed-vent systems introduce two effective alternatives:

- Induced Flow — using ZEVAC to draw fresh odourised gas through the faded section.

- Fresh Gassing — withdrawing ~90% pressure, then blending fresh gas back into the faded zone without taking customers offline.

Benefits

- Achieves full odourisation without venting or flaring methane and VOC emissions

- Improves safety by ensuring reliable gas detectability

- Eliminates community odour concerns.

Key Considerations

- Determine whether a single induced-flow location or multiple points are required.

- Assess available fittings for temporary connections.

- Plan sampling methods to confirm adequate ‘pickling’.

9. Distribution Hot Tapping

Closed-vent compression allows tapping heads, bypass lines and isolated pipe segments to be depressurised without venting, meaning that crews can work without the interruption and risk that blowdown venting introduces. In many cases, the overall operation can be converted to zero emissions with no schedule impact.

Benefits

- Enables zero-emissions hot tapping and plugging (HT&P) operations

- Eliminates the need to clear neighbouring worksites for venting

- Reduces delays and improves crew efficiency.

Key Considerations

- Plan logistics: one unit or two? (Many crews use multiple for speed.)

- Monitor for pressure rebound to confirm true isolation.

- Account for tight urban locations. ZEVAC’s highly compact and mobile equipment is well suited to these operations and can be maneuvered on site easily.

Tremco Pipeline Equipment helped APA Group reduce emissions during routine pipeline maintenance with the ZEVAC Twin HP.

10. Routine Distribution Maintenance Blowdowns

Daily repair and maintenance work in distribution networks rarely lends itself to advanced planning. Crews may need to isolate and depressurise pipe on short notice, which historically has meant venting.

An effective model is to integrate miniaturised closed-vent units directly into maintenance vehicles. This gives crews on-demand capability to withdraw, compress and reinject gas on every job, without needing advance engineering planning or additional project risk assessment.

Benefit

- Zero-release operations become standard, not project-specific.

Key Considerations

- Determine site differential pressure (dP) availability.

- Assess need for single vs multiple mobile units.

- Decide whether to power instrumentation via gas dP or compressed air.

A Clear Path Forward for Reducing Pipeline Venting and Emissions

Across all these applications, the outcome is consistent: closed-vent compression provides a proven alternative to traditional pipeline venting, delivering emissions reduction while improving operational control, safety, and reliability.

For Australian transmission and distribution operators working under increasingly stringent ESG, environmental, and community expectations, ZEVAC systems offer a practical, field-proven way to reduce planned pipeline venting without compromising efficiency, safety, or day-to-day maintenance workflows.

For operators looking to assess venting points, evaluate emissions reduction opportunities, or plan trial deployments, Tremco Pipeline Equipment can support site assessments, equipment selection, and on-site integration to ensure closed-vent solutions are applied effectively in the field.