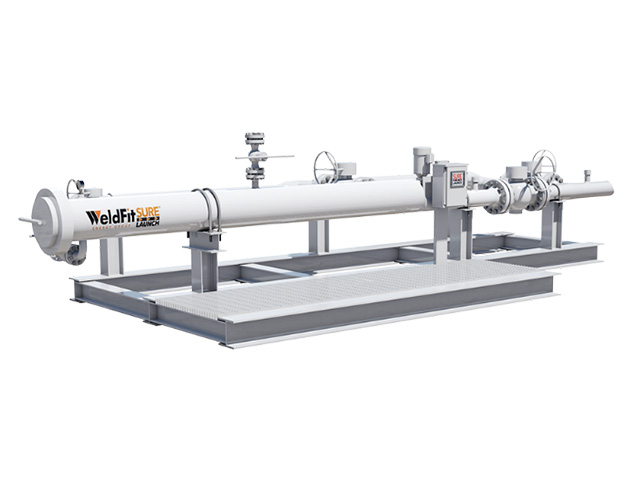

SureLaunch

WeldFit specializes in the design, engineering, manufacturing and quality testing of automated pigging systems that can be utilized to perform four separate pigging functions: liquid recovery, cleaning, batching and in-line inspections. The SureLaunchTM automated pigging system can launch any type of pig individually at pre-set launch intervals through the use of a logic-driven control system and an electrical drive system. The horizontally oriented automatic launcher design is loaded with multiple pigs in one loading operation that allows the launching of a single cleaning pig, batching pig or spherical pig for both liquid and gas pipeline service applications.

KEY FEATURES & BENEFITS:

- Horizontal design eliminates access platforms and lifting equipment to reduce safety risks, transportation costs and field installation costs

- The mechanical launch mechanism ensures pig launches in high and low flow conditions

- The flow-through barrel design of the automated pigging system removes the need to open and close valves for each pig launch, resulting in an increase of the valve operating service-life and a reduction of maintenance costs, environmental emissions and safety risk exposure

- The electric drive system can be powered by 115 VAC or 24 VDC Class 1, Division 1 & 2 compliant power to eliminate supply gas, supply gas treatment and emissions

- Launch system is controlled by drive system that allows any type of pig to be launched to meet operator?s specific pigging requirements

- Standard automated pig launcher is designed to accommodate up to seven cleaning pigs or length of typical in-line inspection tools

- Standard receiver is designed to accommodate up to eight cleaning pigs or length of typical in-line inspection tools

- Primer coated ready for customer desired paint system or painted to customer?s paint specification

- Quick opening closure standard on all units

- Designed with the appropriate quantity and size of nozzles for vents, pressure gauges and drains

- Data Package provided for code compliance

- Hydrostatic pressure tested in accordance with the applicable codes

- All units are skid mounted

- Ethernet/IP address for remote access capabilities

- Designed to applicable safety design factor

- Inspected and designed in accordance to the applicable pipeline codes (B31.8, B31.4, B31.3, Sec. VIII Div. 1)

OPTIONS:

- Semi-automated capabilities without logic-driven controls

- Semi-automated systems can be equipped with electric drive motor or can be manually operated when electric power is not available

- Corrosion coupon holders for monitoring internal corrosion rates

- Pull nozzles for loading in-line inspection tools

- Overlays of trap components for corrosive service applications

- Valve packages available upon request

- In-Field application engineering, project management, training and commissioning services

- Extruded nozzles eliminate tees and reduce girth welds on the outlets during field installation

SPECIFICATIONS:

- Sizes: 4″ nominal to 42″ nominal line pipe

- Barrel Capacity:

- Launcher – 7 Cleaning pigs (2D) or length of one ILI tool

- Receiver – 8 Cleaning pigs (2D) or length of one ILI tool

- Pressure Rating: ANSI 150#, 300#, 600#, 900# & 1500#

- Product: Liquid and Gas Service

- Product Temperature Range: -50° F to 150° F

- Power Options: 24VDC, 115VAC or 230 VAC

- HMI: EXOR eTOP507G 7″ TFT widescreen

- CPU – ARM CORTEX-A8 ? 600 MHz

- User Memory – 128 MB Flash

- Serial – RS-232, RS-485, RS-422

- Ethernet – Two 1-/100 Mbit with integrated switch

- USB – Two Host Interfaces

- Temperature Range: -25° F to 140° F

- Explosion Proof Rating: Class 1, Div. 2 Haz Loc

- Environmental Rating: NEMA 4X / IP66