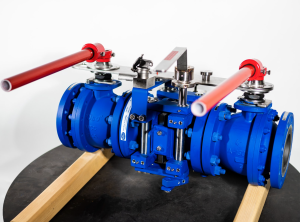

Onis Double Block Bleed and Blind – D3B

Outperform DBB & Reduce human factor – No risk to open the pipe under pressure.

Onis Double Block Bleed and Blind (D3B) is a complete positive isolation solution in one device including one upstream valve, one quick action line blind and one downstream valve. The mechanical safety interlock between the Line Blind and the valves prevents any operation of the Line Blind if the valves remain open, there is no risk to operate under pressure. This patented safety device was designed to avoid operational risk related to human factors in congested areas and critical applications.

How it works ?

The upstream and downstream ball valves are connected to the flanges of the ONIS line blind.

Drains ports are drilled directly in the thickness of the ONIS Line blind’s flanges.

A mechanical interlock avoids the operator to open the pipe to the atmosphere if the ball vales have not been fully shut off.

For example : Fluid is passing through the equipment

To isolate the pipe proceed as hereafter :

- Shut off the upstream and downstream valve

- Open the bleeder ports in order to depressurize and drain the dead volume captured between the two valves which it is the smallest possible volume by design.

- Move the interlock mechanism

- Proceed to the operation of the ONIS line blind, blind pipe and go back to clamp ONIS’ seats position;

- Move backward the mechanical interlock in order to secure the blinding position

Why use a D3B ?

Safety procedure during piping blinding / deblinding operations require every time at least 3 steps :

Shut off the upstream and downstream valves of the blinding / deblinding device which can be a spade or figure 8.

Depressurize the pipe by open drain port upstream and downstream.

Drain the liquid from the pipe if any.

When these 3 steps are done proceed to the unfasten of the flanges’ fasteners (bolts and nuts).

Unfortunately, human mistakes by operating wrongly the valve or selecting the wrong valve, can generate pollution and more dramatic incidents and injuries in case of opening a pipe to the atmosphere without stopping the flow and depressurizing the pipe.

Sometimes the quantity of lost and wasted products between the valves and the pipe blinding device is important and has to be treated or can affect the environment if not collected.

One equipment developed by ONIS answers to safety and environmental requirements during piping blinding operation: ONIS D3B

Technical specifications

All Double Block Bleed and Blind are designed following these specifications:

- Forged bodies

- Spreading design with no internal mechanism

- Only four gaskets located on the slide gate

- Perfect sealings – 100 % full bore

LINE BLIND SET IN FACTORY: NO APPRECIATION BY OPERATOR